PWM (Pulse Width Modulation) is a technique widely used to control the speed and vibration force of DC or vibration motors. When a high frequency PWM signal is applied to a motor, the average voltage that drives the motor is that signal. This allows precise control of the motor's speed and vibrational force. It is an important tool in a variety of applications including robotics, industrial machinery, and consumer electronics.

Understand the basics of PWM signals

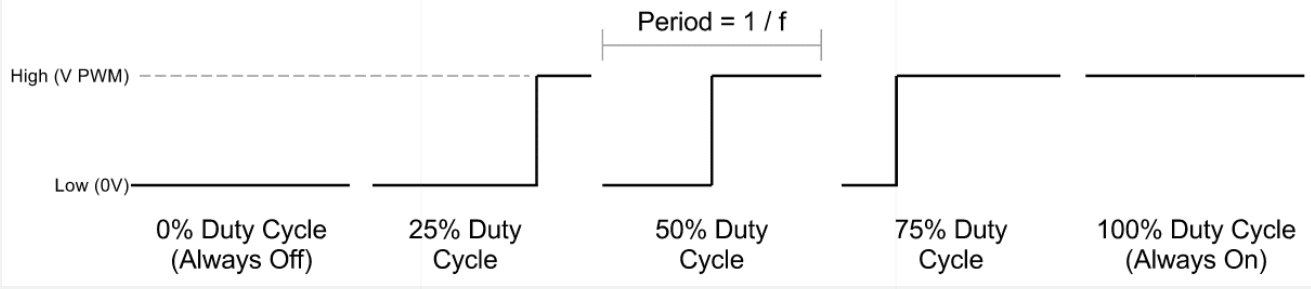

To use PWM to control the speed and vibration force of a motor, it is important to understand the basics of PWM signals. A PWM signal consists of a series of pulses, where the pulse width (called the duty cycle) determines the average voltage applied to the motor. By adjusting the duty cycle of the PWM signal, the effective voltage and current delivered to the motor can be controlled, thereby adjusting the speed and vibration force of the motor.

When applying PWM to a coin vibration motor, the frequency of the PWM signal plays a crucial role in determining the performance of the motor. Higher PWM frequencies allow for smoother, more precise control of the motor's speed and vibration force. Furthermore, the PWM frequency should be chosen carefully to avoid any undesirable effects such as audible noise or mechanical resonance in the motor.

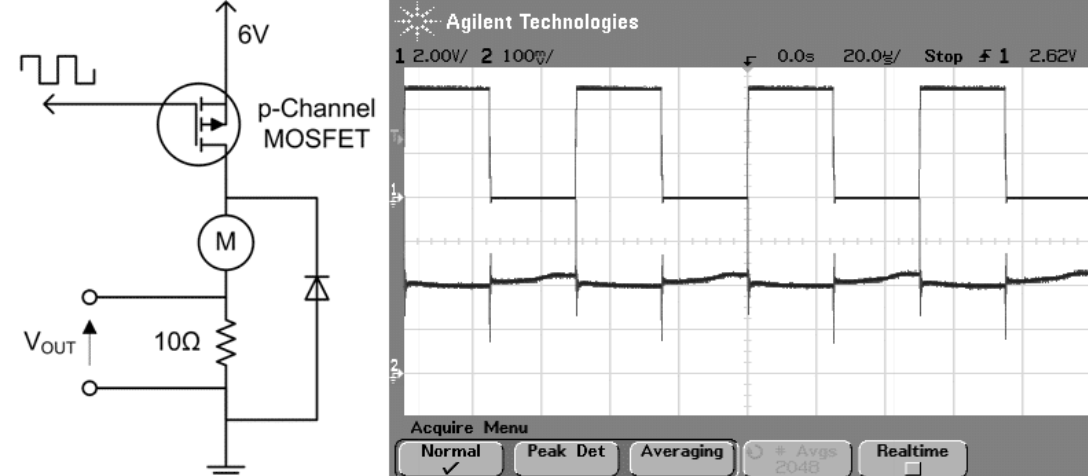

Example of motor driven by a PWM signal

Choose the correct PWM controller or microcontroller

To effectively use PWM to control vibration motor speed and vibration force, a suitable PWM controller or microcontroller must be selected that can generate the required PWM signal. The controller should be able to generate a high-frequency PWM signal with an adjustable duty cycle. So it can meet the specific requirements of the application.

Additionally, it is important to consider the small vibration motor's specifications and operating characteristics when implementing PWM control. Factors such as voltage, current, mechanical, and electrical characteristics of the motor should be considered to ensure safe and efficient operation.

PWM duty cycles

In summary

PWM is a powerful tool for controlling the speed and vibration force of a DC vibration motor. By understanding the principles of PWM signals and selecting an appropriate PWM controller, precise and reliable control of motor performance can be achieved. It is an indispensable technology in motor control and vibration applications.

Consult Your Leader Experts

We help you avoid the pitfalls to deliver the quality and value your micro brushless motor need, on-time and on budget.

Post time: Apr-20-2024