Leader Micro Electronic’s SMD/SMT reflow series mini vibration motor are an excellent choice for fully automated, high-speed mass production utilizing pick and place machines. This is the only series of vibration motor available on tape and reel. If hand soldering the motor to the PCB ( i.e. making prototypes), do not use flux as this can enter the motor and cause it to fail. This series of motors cannot be washed after the reflow process.

Our mini vibrating motor SMD, surface mount vibration motors are packaged on tape / reels of 1000 pieces per reel and are designed to be pick-and-placed directly from the reel. They are an excellent choice for high volume mass production. They have a “core” which allows them to withstand the high temperatures associated with the reflow soldering process. These SMD vibrator motors can be damaged by excessive heat. Please be sure to follow the reflow oven temperature profile found in the motors data sheet. If these motors will be hand soldered ( ie. making prototypes) , do not use flux and use a low wattage iron for as short a time period as possible. Please note that these vibration motors CAN NOT be washed.

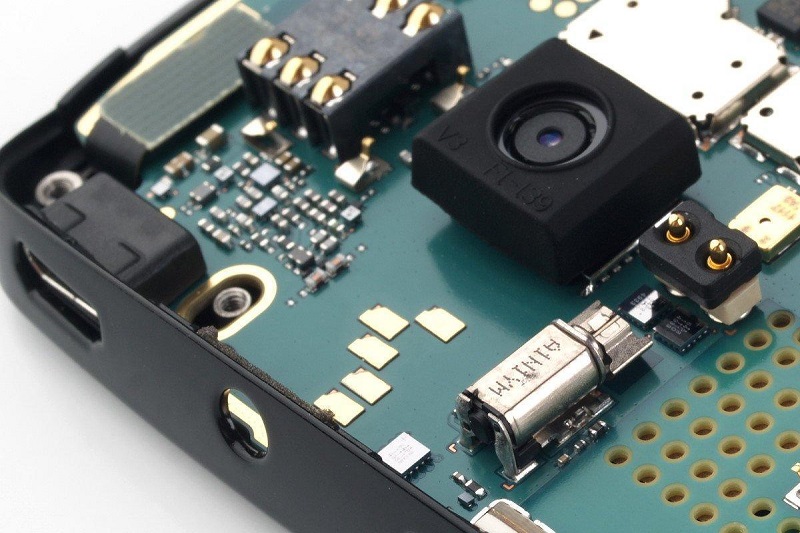

Spring Contact smt vibrating motor:

This series of surface mount vibration motors, with spring contacts, make an excellent choice for a variety of reasons. Unlike our SMT Reflow motors, these motors are NOT designed to be soldered to the PCB. The contact springs on these motors simply mate with contact pads on the PCB. This type of motor offers some distinct advantages as follows:

Lower Cost:This series of motors are approx. 10% lower in cost than SMT reflow vibration motors.

Efficient Vibration Energy Transfer: These motors can be mounted in the plastic case of a products housing where it is more likely to be felt and less likely to be dampened like motors that are mounted on a PCB.

Increased Reliability: Vibration has been known to contribute to product failures. Minimizing the amount of such energy transfer to the PCB can only be helpful in this regard.

Superior Serviceability: In applications where the motor is subjected to extreme duty cycles, that exceed the motors rated life, premature motor failure may occur. Replacing this type of vibrator motor, even in the field, is fast and efficient as no soldering in required to remove and replace it. (continued below)

Post time: Aug-23-2018