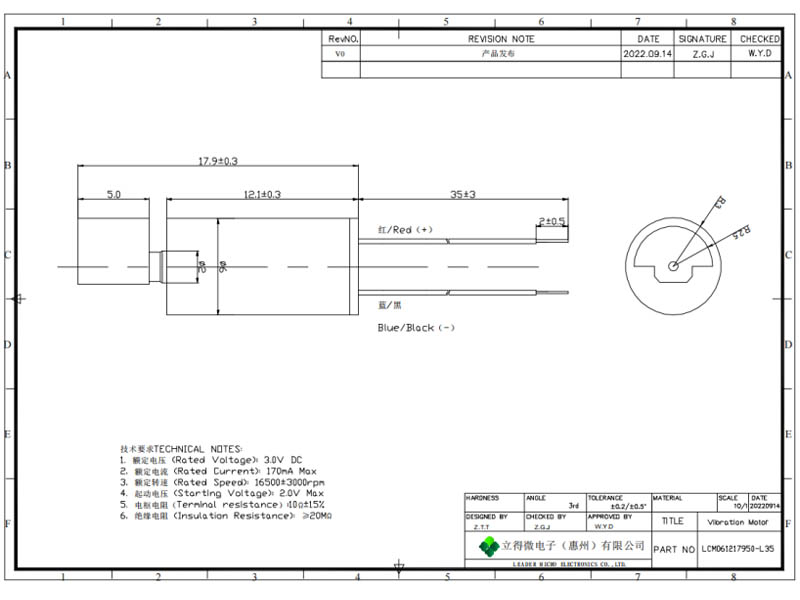

Dia 6*12mm Cylindrical Motor | Coreless Motor | LEADER LCM-0612

Main Features

Specification

| Technology Type: | BRUSH |

| Diameter (mm): | 6.0 |

| Body Length(mm): | 12 |

| Rated Voltage (Vdc): | 3.0 |

| Operating Voltage (Vdc): | 2.0~3.0 |

| Rated Current MAX (mA): | 170 |

| Rated Speed (rpm, MIN): | 16500±3000 |

| Vibration Force (Grms): | 0.6 |

| Part Packaging: | Plastic Tray |

| Qty per reel / tray: | 200 |

| Quantity - Master box: | 5000 |

Application

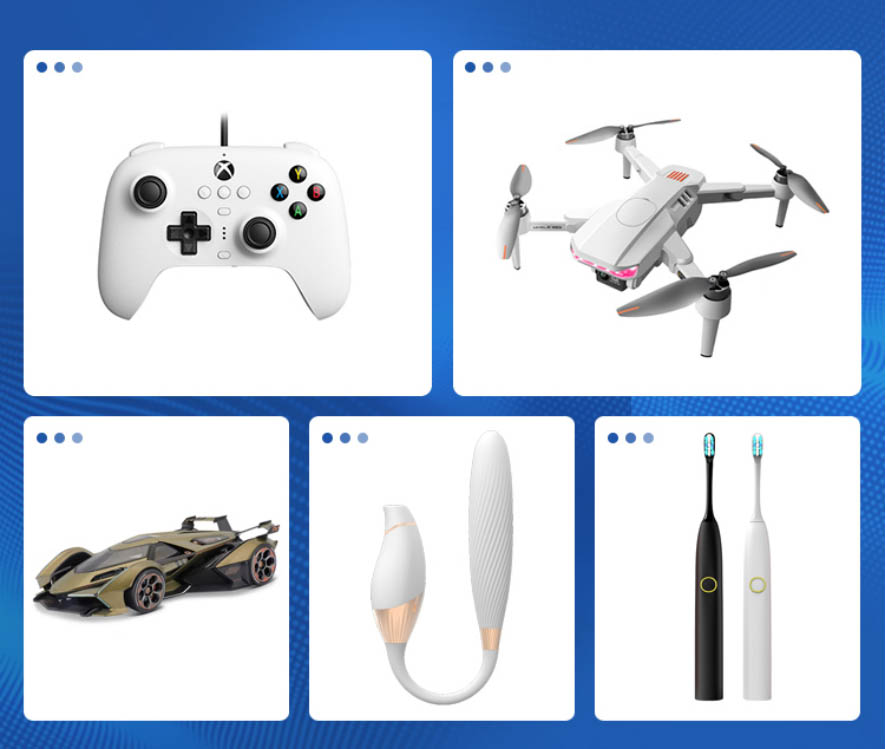

The coreless motors makes radial vibration, and it has the following advantages: lower noise, lower starting voltage, lower power consumption. The main applications of cylinder motor are gamepad, model airplane, adult products, electric toys and electric toothbrush.

Working with Us

FAQ For 6*12mm Cylindrical Motor

Answer: Yes, coreless motor can be operated in reverse by changing the polarity of the input voltage.

Answer: The LCM0612 coreless motor may not be suitable for use in wet environments due to the lack of waterproofing measures.

Answer: This coreless motor typically does not require lubrication, as the rotor and stator are designed to operate with minimal friction.

A cylindrical motor refers to an electric motor that has a cylindrical shape. Unlike traditional motors with a flat or pancake design, cylindrical motors have a cylindrical form factor. These motors are commonly utilized in different types of motors, including eddy current motors with soft steel, hysteresis motors utilizing weak permanent magnets, and brushless motors featuring a bonded magnet.

Cylindrical motors are designed to be compact and efficient. With their cylindrical shape, these motors can have larger diameters and lengths, providing ample space for the rotor and stator. This design enables the motor to deliver increased power and torque while maintaining a relatively small size. Moreover, the cylindrical form factor facilitates flexible mounting and installation options, allowing the motor to be conveniently mounted in various orientations.

Coreless Motor Manufacturer

A cylindrical motor resembles a cylinder or rectangular prism in shape. It is also known as a coreless motor since its internal structure is hollow. Compared to traditional iron-core motors, cylindrical motors are lighter, smaller and more efficient. Because they are made of a hollow aluminum or copper rotor with no iron core, which reduces weight. Cylindrical motors are commonly used in high-speed and high-precision applications. Such as drones, robots, medical equipment and automated control systems.

As a professional micro coreless motor manufacturer and supplier in China, we can meet customers' needs with custom high quality coreless motor. If you are interested, welcome to contact Leader Micro.

Quality Control

We have 200% inspection before shipment and the company enforces quality management methods, SPC, 8D report for defective products. Our company has a strict quality control procedure, which mainly tests four contents as follow:

01. Performance Testing; 02. Waveform Testing; 03. Noise Testing; 04. Appearance Testing.

Company Profile

Established in 2007, Leader Micro Electronics (Huizhou) Co., Ltd. is a high-tech enterprise integrating R&D, production, and sales of micro vibration motors. Leader mainly manufactures coin motors, linear motors, brushless motors and cylindrical motors, covering an area of more than 20,000 square meters. And the annual capacity of micro motors is nearly 80 million. Since its founding, Leader has sold nearly a billion of vibration motors all over the world, which are widely used on about 100 kinds of products in different fields. The main applications conclude smartphones, wearable devices, electronic cigarettes and so on.

Reliability Test

Leader Micro has professional laboratories with a full set of testing equipment. The main reliability testing machines are as below:

01. Life Test; 02. Temperature & Humidity Test; 03. Vibration Test; 04. Roll Drop Test;05. Salt Spray Test; 06. Simulation Transport Test.

Packaging & Shipping

We support air freight, sea freight and express.The main express are DHL, FedEx, UPS, EMS, TNT etc. For the packaging: 100pcs motors in a plastic tray >> 10 plastic trays in a vacuum bag >> 10 vacuum bags in a carton.

Besides, we can provide free samples on request.