Micro vibration motors, perfect for lightweight applications or where space is at a premium. They include miniaturised DC coreless motors with eccentric masses, both in cylindrical and coin form . They will fit a variety of different applications and power needs.

Let’s take a look at its features, applications and usage considerations.

Micro vibration motor features:

1, can be stepless speed regulation

As long as the opening of the intake or exhaust valve is controlled, that is, the flow rate of the compressed air is controlled, the output power and the rotational speed of the motor can be adjusted.

The purpose of adjusting the speed and power can be achieved.

2, can forward or reverse

Most motors simply use a control valve to change the direction of the motor’s intake and exhaust, which enables forward and reverse rotation of the motor’s output shaft and instantaneous commutation.

In the forward and reverse conversion, the impact is small. A major advantage of motor commutation operation is its ability to rise to full speed almost instantaneously.

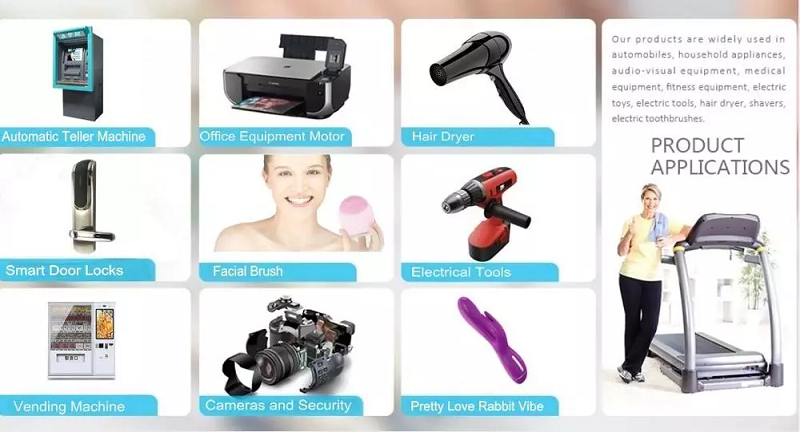

waterproof vibration motor application

1、Haptic feedback & vibration alerting for consumer products.

2、 Industrial handheld equipment, such as harsh environment.

3、 Adult toys (waterproof vibration motor).

4、 Medical equipment, such as surface cleaned or sterilised.

5、 Performance indicators for athletes.

6、Wearable vibrating sleeves to stimulate blood flow for fitness.

7、Haptic feedback enabled clothing, allowing the operator to keep two hands free, useful for security purposes, musicians.

8、 Washable vibrating collars or clothing for animals.

9、 Vibration alerting, especially for industrial control panels.

10、 Sorting machines,

11、 Mixing Powders and emulsifying liquids,

12、 Aiding the movement of material down chutes, hoppers.

13、 Bulkheads and ruggedised / industrial control panels or dashboards.

14、 Other applications which require a waterproof vibration motor.

Matters to be paid attention to when using micro vibrating motor

1、Please lay the motors carefully in transportation to avoid any serious damage to the motor body or its electric function because of collision.

2、Please use the motor according to the instruction of this product specification, or else, it will be bad for motor’s life.

3、Please do not store motor in high temperature,Low temperature, high humidity environment. Condensation of atmosphere must be avoided in motor usage or opening the packaging of the motor.

4、For proper operation. storage and operating environment must not contain corrosive gases. For example H2S. SO2. NO2. CL2. etc. In addition storage environment must not have materials that emit corrosive gases especially from silicon. cyanic. formalin and phenol group. In the mechanism or the set. existence of corrosive gases may cause no rotation in motor.

5、 Please don’t stall the shaft for a long time after powering, and not to touch the weight when motor is rotating.

6、 There should be no sundries (such as grain, fibre, hair, small tape, glue etc.) in the shaft end play.

High quality vibration motor manufacturer, customizable, fast delivery, global delivery, contact us now

Post time: Mar-27-2019