LRA (Linear Resonant Actuator) Motor Manufacturer

Leader Micro company’s LRA vibrator creates vibration and haptic feedback in Z-direction and X-direction. It's acknowledged to outperform ERMs in response time and lifespan, making it favorable for the handset and wearable vibration technology.

LRA vibration motor deliver stable frequency vibrations while consuming less power and enhancing the quality of haptic experiences for users. It achieves vertical vibration through electromagnetic force and resonance mode, which triggered by sine wave-generated vibrations.

As a professional micro linear motor manufacturer and supplier in China, we can meet customers' needs with custom high quality linear motor. If you are interested, welcome to contact Leader Micro.

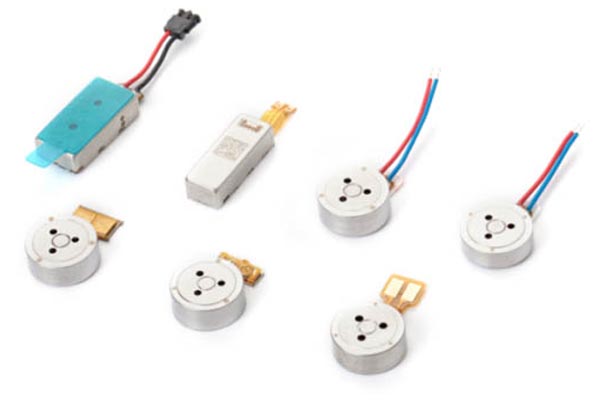

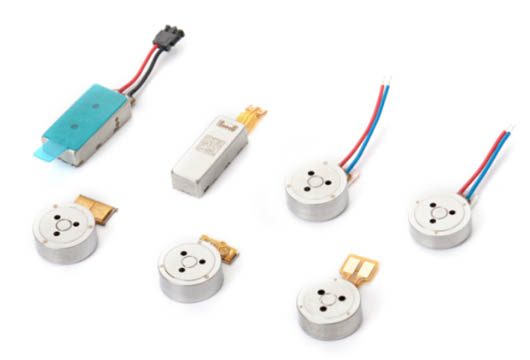

What We Produce

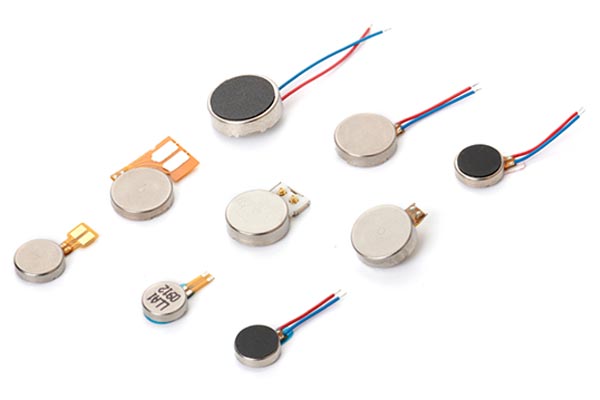

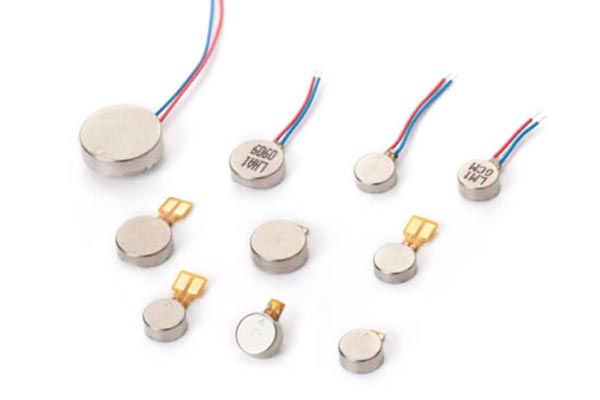

The LRA (Linear Resonant Actuator) motor is an AC-driven vibration motor with a diameter primarily of 8mm, which is commonly used in haptic feedback applications. Compared to traditional vibration motors, LRA vibration motor are more energy-efficient. It offers a more precise response with a fast start/stop time.

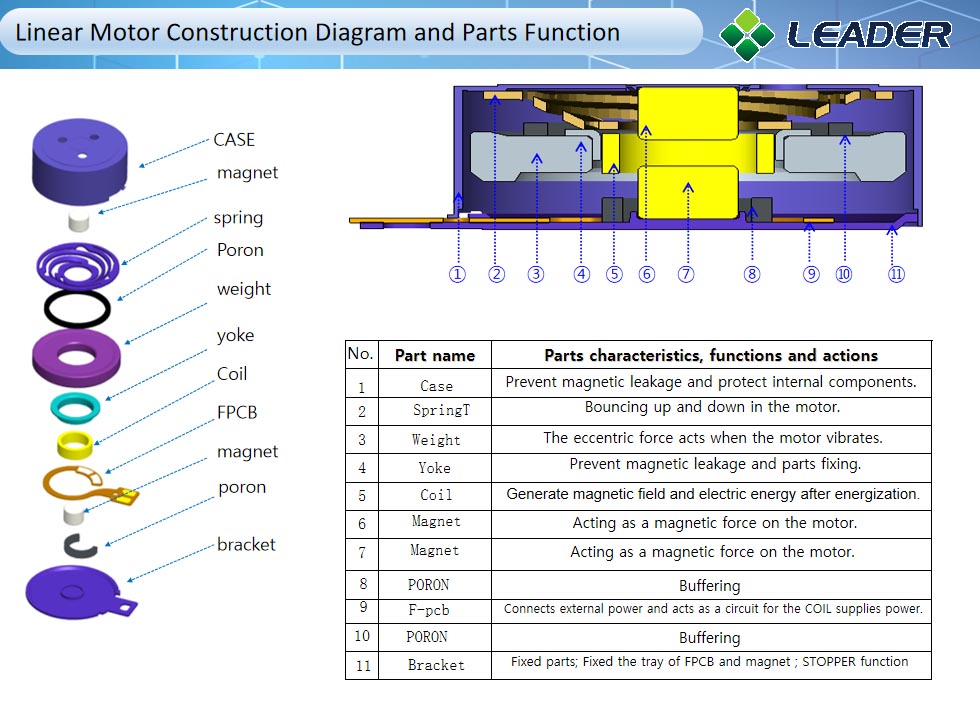

Our coin-shaped Linear Resonant Actuator (LRA) is designed to oscillate along the Z-axis, perpendicular to the motor surface. This specific Z-axis vibration is very effective in transmitting vibration in wearable applications. In high-reliability (Hi-Rel) applications, LRA motor can be a viable alternative to brushless vibration motors because the only internal component subject to wear and failure is the spring.

Our company is committed to providing high-quality linear resonant actuator with customizable specifications to cater to the diverse needs of our clients.Interested in lightweight and efficient solutions? Discover how our coreless motors deliver exceptional speed and precision!

Z-axis Vibration Motor

X-axis Vibration Motor

| Models | Size(mm) | Rated Voltage(V) | Rated Current (mA) |

Frequency |

Voltage |

Acceleration |

| LD0825 | φ8*2.5mm | 1.8VrmsAC

Sine wave |

85mA Max | 235±5Hz | 0.1~1.9 Vrms AC |

0.6Grms Min |

| LD0832 | φ8*3.2mm | 1.8VrmsAC

Sine wave |

80mA Max | 235±5Hz | 0.1~1.9 Vrms AC |

1.2Grms Min |

| LD4512 | 4.0Wx12L 3.5Hmm |

1.8VrmsAC

Sine wave |

100mA Max | 235±10Hz | 0.1~1.85 Vrms AC |

0.30Grms Min |

Still not finding what you're looking for? Contact our consultants for more available products.

Application

The linear resonant actuators have some remarkable advantages: extremely high lifetime, adjustable vibrating force, fast response, low noise. It is widely used on electronic products that require haptic feedbacks such as smartphones, wearables, VR headsets and gaming consoles, enhancing user experiences.

Smartphones

linear vibration motor is commonly used in smartphones for haptic feedback, such as providing tactile responses for typing and pressing buttons. Users can feel the precise feedback through their fingertips, which improves overall typing accuracy and reduces typing errors. Additionally, lra haptic motor can provide vibration alerts for notifications, calls and alarms. It can improve overall user engagement.

Wearables

Linear motor vibration are also found in wearables, such as smartwatches, fitness trackers and other portable devices. Linear resonant actuators can provide vibration alerts for incoming calls, messages, emails or alarms, allowing users to stay connected with the world without interrupting their daily activities. Additionally, micro linear motor can provide haptic feedback for fitness tracking, such as tracking steps, calories and heart rate.

VR Headsets

Custom linear motors can also be found in VR headsets, such as Oculus Rift or HTC Vive, for sensory immersion. Custom linear motor can deliver a range of vibrations that can simulate various in-game sensations, such as shooting, hitting or explosions. lra motors add another layer of realism to virtual reality experiences.

Gaming Consoles

Custom linear motor is also used in gaming controllers for haptic feedback. These motors can provide vibration feedback for important in-game events, such as successful hits, crashes or other game actions. They can give players a more immersive gaming experience. These vibrations can also provide physical cues to the players, such as alerting them when a weapon is ready to fire or reloading.

In summary, the use of linear actuator vibration motors is widespread, ranging from smartphone to gaming consoles, and it can significantly improve user experiences in various applications.

Linear Resonant Actuators (LRAs) Driving Principle

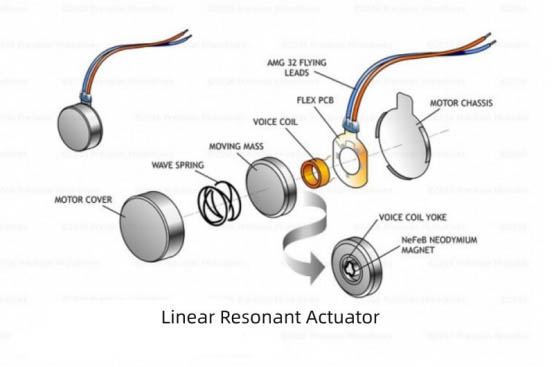

Haptic motors are based on the principle of resonant vibration. The device consists of a coil, a magnet, and a mass attached to the magnet. When an AC voltage is applied to the coil, it generates a magnetic field that interacts with the magnet, causing the mass to vibrate. The frequency of the AC voltage applied to the coil is tuned to match the resonant frequency of the mass, resulting in a large displacement of the mass.

Linear vibration motors have many advantages as compared to other types of actuators. One of the most significant advantages is its low power consumption, which makes it ideal for use in portable and battery-operated devices. lra linear resonant actuator also generates highly precise and controllable vibrations, which can be used for a variety of purposes. Another advantage of linear vibration actuator is its long operational lifespan, which makes it highly reliable and durable. It also has a fast response time, which enables it to produce vibrations quickly and accurately.

Overall, vibrating actuator is a highly efficient and effective actuator that has been widely used in a variety of applications. Its ability to produce precise and controllable vibrations, combined with its low power consumption and long operational lifespan, make it an ideal choice for many different types of devices and technologies.

Characteristics and Functions of LRA Motor

Characteristics:

- Low voltage operation: LRA motor has a low voltage operation with 1.8v, making it ideal for small electronic devices that require minimal energy usage.

- Compact size: The compact size of LRA motor allows it to be used in devices with limited space.

- Fast start/stop time: The LRA motor has a fast start/stop time, allowing it to provide more precise haptic feedback to the user.

- Low noise operation: These motors run quietly, which is important for devices that require minimal noise generation.

- Customizable frequency and amplitude settings: The frequency and amplitude settings of the LRA motor can be customized to suit specific device requirements.

Functions:

- LRA motor delivers precise and efficient haptic feedback to enhance user experience with the device.

-The tactile sensation provided by the LRA motor that enhances the user's experience with the device, making it more enjoyable to use.

- LRA motors use little power, making them ideal for devices designed to conserve energy.

- LRA motors provide a more controlled and consistent vibration response than traditional vibration motors.

- The frequency and amplitude settings of the LRA motor can be adjusted to meet different device specifications.

Linear Resonance Actuator Related Patents

Our company has obtained several patent certificates related to our LRA (Linear Resonant Actuator) motor technology, which highlights our industry-leading innovation and research efforts. These patents cover various aspects of the vibration actuator technology, including its design, manufacturing process and application. Our patented technologies enable us to provide high-quality, energy-efficient and customizable LRA motors that cater to the unique needs of our customers.

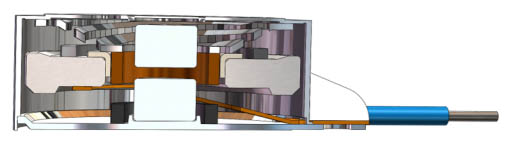

One of the patents is about a design of linear vibration motor with large amplitude . A damping pad is installed on the other side of the mounting side of the stator assembly and the rotor assembly. The damping pad can avoid hard collision with the housing when the rotor assembly vibrates inside the housing, which prolongs the service life of the linear vibration motor. A magnetic loop is placed on the outside of the coil to increase the amplitude of the linear vibration motor. It can also optimize the haptic experience when using electronic devices equipped with linear vibration motors.

Overall, our patented LRA motor technology sets us apart from other industry players, allowing us to provide high-quality, innovative and energy-efficient products to our customers. We remain committed to driving technology innovation, and providing cutting-edge solutions to enhance the user experience in electronic devices.

Get Micro LRA Motors in Bulk Step-by-step

Linear Haptic Motor FAQ

In contrast to vibration motors, which typically utilize electromechanical commutation, LRA (linear resonant actuator) vibration motors utilize a voice coil to drive a mass, operating in a brushless manner. This design minimizes the risk of failure because the only moving part subject to wear is the spring. These springs undergo comprehensive finite element analysis (FEA) and operate within their non-fatigue range. Failure modes are mainly related to the aging of internal components due to reduced mechanical wear.

(Finite element analysis (FEA) is the use of calculations, models and simulations to predict and understand how an object might behave under various physical conditions.)

As a result, LRA vibration motors have significantly longer mean time to failure (MTTF) than conventional brushed eccentric rotating mass (ERM) vibration motors.

LRA Motors generally have a longer lifespan than the other motors. The lifespan under the condition of 2 seconds on/1 second off is one million cycles.

Linear vibration actuator is compatible with a wide range of electronic devices, such as wearables, medical devices, and gaming controllers.

Yes, a motor driver is required to operate the linear vibration motors. The motor driver can also help to control the vibration intensity and protect the motor from overloading.

The history of linear resonant actuators (LRA) can be traced to the use of eccentric rotating mass (ERM) vibration motors in personal electronic devices. Motorola first introduced vibration motors in 1984 in its BPR-2000 and OPTRX pagers. These motors provide a silent way to alert the user through vibration. Over time, the need for more reliable and compact vibration solutions led to the development of linear resonant actuators. Also known as linear actuators, LRAs are more reliable and often smaller than traditional ERM motors. They quickly became popular in haptic feedback applications and basic vibration alerts. Nowadays, LRA is widely used in various electronic devices such as mobile phones, smartphones, wearable devices, and other small devices that require vibration functionality. Their compact size and reliability make them ideal for providing tactile feedback to enhance the user experience. Overall, the evolution from ERM motors to LRAs in personal electronic devices has revolutionized the way devices provide feedback to users, providing a more refined and efficient vibration experience.

Unlike traditional brushed DC vibration motors, linear resonant actuators (LRA) require an AC signal at the resonant frequency to operate properly. They cannot be driven directly from a DC voltage source. The leads of an LRA usually come in different colors(red or blue), but they have no polarity. Because the drive signal is AC, not DC.

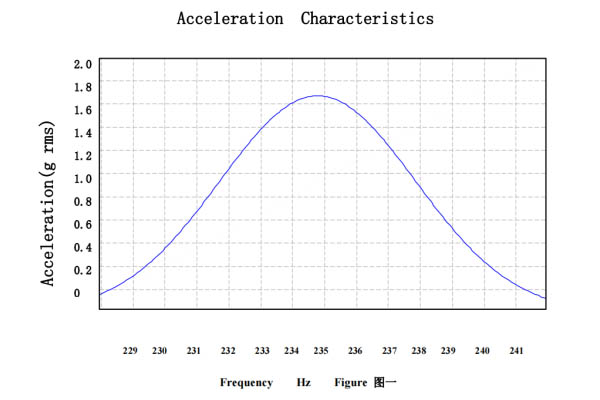

In contrast to brushed eccentric rotating mass (ERM) vibration motors, adjusting the amplitude of the drive voltage in the LRA only affects the applied force (measured in G-force) but not the vibration frequency. Due to its narrow bandwidth and high quality factor, applying frequencies above or below the LRA's resonant frequency will result in reduced vibration amplitude, or no vibration at all if it deviates significantly from the resonant frequency. Notably, we offer broadband LRAs and LRAs operating at multiple resonant frequencies.

If you have any specific requirements or further inquiries please let us know and we will be happy to assist you.

RA (Linear Resonant Actuator) is an actuator that generates vibration. It is commonly used in devices such as smartphones and game controllers to provide tactile feedback. LRA works on the principle of resonance.

It consists of coils and magnets. When alternating current passes through the coil, it creates a magnetic field that interacts with the magnet. This interaction causes the magnet to move back and forth quickly.

The LRA is designed in such a way that it reaches its natural resonant frequency during this movement. This resonance amplifies vibrations, making them easier for users to detect and perceive. By controlling the frequency and intensity of alternating current passed through the coil, the device can produce different levels and patterns of vibrations.

This allows for a variety of haptic feedback effects, such as notification vibrations, touch feedback, or immersive gaming experiences. Overall, LRAs use electromagnetic forces and resonance principles to generate vibrations that produce controlled and perceptible movement.

You need to provide the basic specification of the motor, such as: Dimensions, Applications, Voltage, Speed. It’s better to offer application prototype drawings to us if possible.

Our mini DC motors find applications in various industries such as home appliances, office equipment, healthcare, high-class toys, banking systems, automation systems, wearable device, payment equipment, and electric door locks. These motors are designed to provide reliable and efficient performance in these diverse applications.

Diameter 6mm~12mm Dc Micro Motor, Electric Motor, Brush Dc Motor, Brushless Dc Motor, Micro Motor, linear motor, LRA motor, cylinder coreless Vibration Motor, smt motor Etc.

Know More About LRA Linear Vibration Motors

1.History of the LRA(linear resonant actuator)

The use of ERM vibration motors in personal electronic devices was first pioneered by Motorola in 1984. The BPR-2000 and OPTRX pagers were among the first devices to incorporate this feature, providing silent call alerts and compact vibration feedback to the user. Today, LRAs (also known as linear actuators) offer high reliability in small sizes. They are commonly used in haptic feedback applications and basic vibration alarm functions. Linear vibration motors are widely used in mobile phones, smartphones, wearable devices and other small devices that require vibration functions.

2.Driver IC

Leader micro linear motor LD0832 & LD0825 should be used with a driver IC such as the TI DRV2604L or DRV2605L. TI (Texas Instruments) sell an evaluation board with this IC chip on it. Check the link: https://www.ti.com/lsds/ti/motor-drivers/motor-haptic-driver-products.page

If you want more cost-effective IC, we can recommend you Chinese suppliers with same performance but cheap price.

3.The LRA As A Circuit Component

When LRA motors are integrated into a circuit, they are often simplified beyond their equivalent circuit, particularly when driven by a dedicated LRA driver chip such as DRV2603. By connecting the LRA to the appropriate pins of a stand-alone IC, designers and engineers can save time and focus on other aspects of the system.

Despite the production of back EMF by LRAs, many LRA drivers utilize this effect as a sensing mechanism. Certain driver IC measure the back EMF. They use this information to adjust the frequency of the drive signal to find the resonance. It enables the product to operate within closer limits and levels regardless of conditions or age.

It's important to note that LRA motors are effectively brushless. They do not suffer from the electromagnetic emissions associated with commutator arcing in DC ERM motors. This characteristic, similar to brushless ERM motors, generally makes LRAs suitable for ATEX certified equipment.

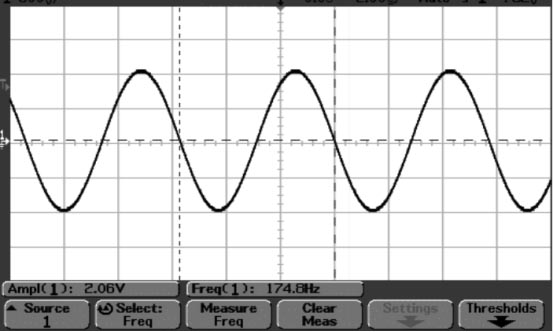

4.Driving Linear Resonant Actuators / Linear Vibrators

LRA linear vibrators require an AC signal to operate, similar to speakers. It is best to use a sine wave signal at the resonant frequency, as shown in the figure below.

Of course, the amplitude of the drive waveform can be modulated to produce more advanced tactile feedback effects.

5.Extended Lifetime For Linear Vibrators

LRA vibration motors differ from most vibration motors in that they utilize a voice coil to drive the mass, making them effectively brushless.

This design minimizes the possibility of spring failure, which is modeled using finite element analysis (FEA) and operates in a non-fatigue zone. Because mechanical wear is minimal and the main failure mode is limited to the aging of internal components, the mean time to failure (MTTF) is significantly longer compared to conventional brushed eccentric rotating mass (ERM) vibration motors.

Consult Your Leader Linear Motor Manufacturers

We help you avoid the pitfalls to deliver the quality and value your micro LRA motors need, on-time and on budget.