Vibration Motors: Eccentric Rotating Mass (ERM) And Linear Resonant Actuators(LRA)

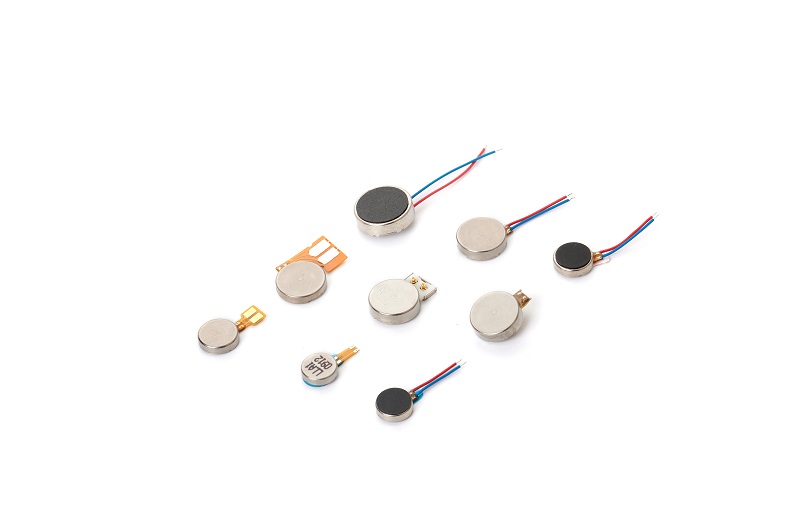

LEADER Micro Motor is proud to offer a wide range of DC vibration motors, with samples available at any time. Featuring a variety of technologies and sizes smaller than Ø12 mm, our motors are renowned for their high-quality craftsmanship and affordability. Additionally, we offer highly customizable options to meet the specific requirements of different applications.

Vibration motor technologies

Our team of engineers specializes in creating vibration and tactile feedback solutions utilizing four unique motor technologies. Each technology has its own characteristics, advantages and trade-offs. By understanding the unique advantages and compromises of each technology, we are able to design tailor-made solutions to meet the specific requirements of our customers' applications.

Eccentric Rotating Mass (ERM) Vibration Motors

ERM motors are original technology for generating vibrations and offer several advantages. They are user-friendly, come in a wide range of sizes, and can be flexibly adjusted in vibration amplitude and frequency to suit any application.

These coin type vibration motor can be found in a variety of devices, from small smart watches to large truck steering wheels. At our company, we specialize in designing and manufacturing vibration motors with different motor technologies including iron core, coreless and brushless. These motors are available in cylindrical and coin-type forms.

One of the main advantages of ERM motors is their simplicity and ease of use.

DC motors, in particular, are easy to control, and if longevity is important, 8mm flat coin vibration motor can be used.

However, there are some compromises to consider. There is a geometric relationship between vibration amplitude and frequency and speed, which means that it is not possible to adjust amplitude and frequency independently.

To meet different requirements, we offer three motor structures and technologies. Iron core motors offer a lower cost option, coreless motors offer a balance between cost and performance, and brushless motors offer the highest performance and longest life.

Linear Resonant Actuators(LRA)

Linear resonant actuators (LRA) function more like a speaker than a traditional motor. Instead of cones, they consist of a mass that moves back and forth through a voice coil and spring.

A distinctive feature of the LRA is its resonant frequency, at which the amplitude reaches its maximum. Deviating even a few Hertz from this resonant frequency can result in significant losses in vibration amplitude and energy.

Due to slight manufacturing differences, the resonant frequency of each LRA will be slightly different. Therefore, a special driver IC is required to automatically adjust the drive signal and allow each LRA to resonate at its own resonant frequency.

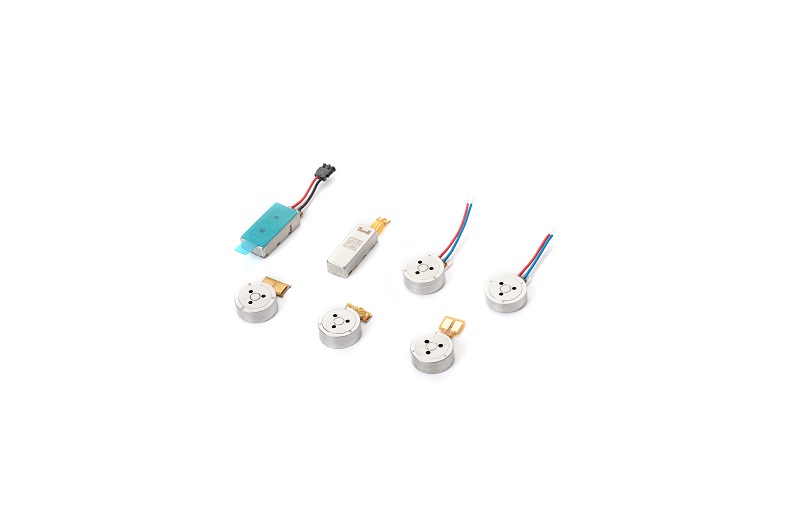

LRAs are commonly found in smartphones, small touchpads, tracker pads, and other handheld devices weighing less than 200 grams. They come in two main shapes - coins and bars - as well as some square designs. The axis of vibration may vary depending on the form factor, but it always occurs along a single axis (unlike an ERM motor which vibrates on two axes).

Our product range is constantly evolving to meet specific customer needs. If you are considering using an LRA, it will be helpful to consult with one of our application design engineers.

Typical vibration motor form factors

Regardless of the vibration motor technology used, a variety of standard form factors and design considerations are common across industries. These factors mainly revolve around the electrical connection interface. Here are some descriptions of these typical form factors to help you determine your preferred solution.

How we can help

Although integrating a vibration motor into your application may seem simple, achieving reliable mass production may be more challenging than expected.

It is critical to consider a variety of factors, including:

Vibration amplitude and frequency,

Motor winding tuning of the power supply,

Audible noise levels,

Motor life,

Tactile response characteristics,

EMI/EMC electrical noise suppression,

...

With our manufacturing and volume production, we can take care of this aspect so that you can focus on enhancing the value-added functionality of your application.

Consult Your Leader Experts

We help you avoid the pitfalls to deliver the quality and value your micro brushless motor need, on-time and on budget.

Post time: Oct-27-2023