With over a decade of experience, LEADER are a leading manufacturer of the smallest BLDC motors. We delivered precision-engineered solutions for various applications. Our cutting-edge technology and expert team ensure that each motor provides exceptional performance and reliability, meeting the highest industry standards.

Our commitment to quality and innovation sets us apart. We leverage advanced manufacturing techniques and serious quality control processes to produce compact BLDC motors that excel in durability and efficiency. We can tailor vibration motor solutions to your specific product needs.

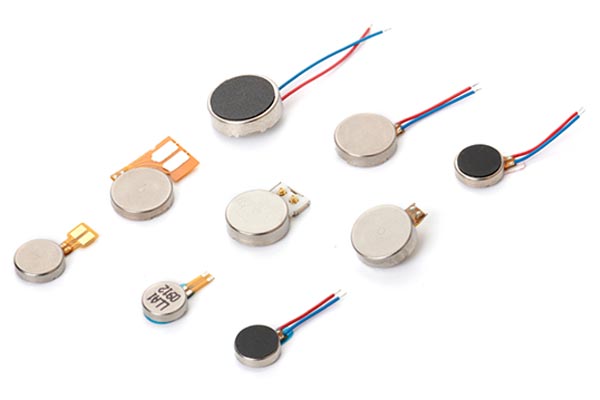

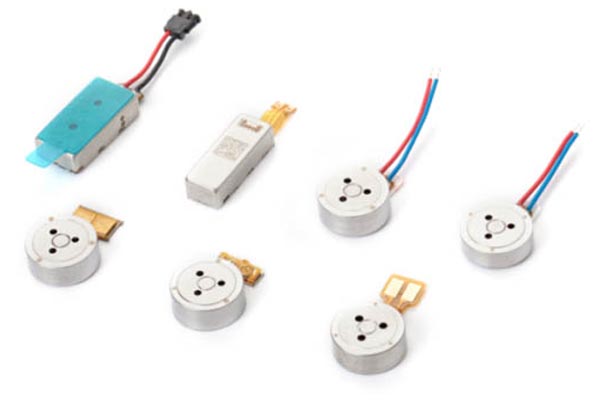

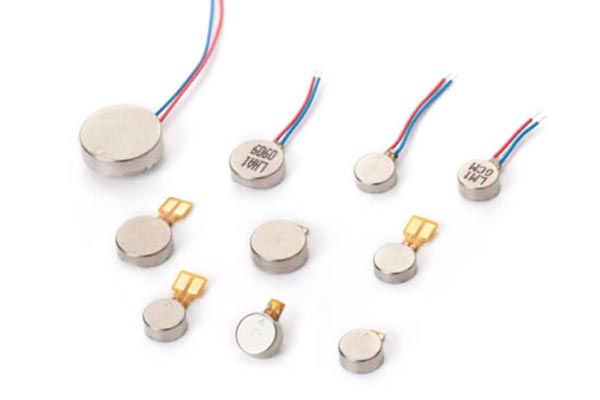

Smallest BLDC Motor Type

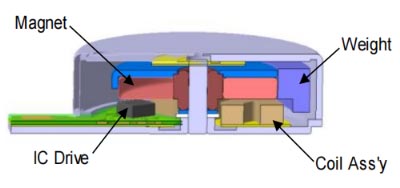

As the tiniest BLDC coin vibration motor currently available on the market, the LBM0518, 0525, 0620 is ideally suited for ultra-lightweight wearable devices—smart rings and similar light-duty wearables included.

Its FPC contact pads are engineered to connect seamlessly with contact springs, and we also offer custom FPC manufacturing services tailored to your specific design requirements.

For easy installation, the motor case features double-sided adhesive on its bottom. A key advantage lies in its integrated driver IC: since the BLDC motor comes with a built-in driver, there’s no need for an external one.

It’s crucial to note the voltage polarity, as an incorrect connection may result in damage to the internal driver IC. This device exclusively operates on DC voltage, and PWM signals are not compatible with driving this BLDC motor.

| Models | Size(mm) | Rated Voltage(V) | Rated Current (mA) | Rated(RPM) | Voltage(V) |

| LBM0620 | φ6*2.0mm | 3.0V DC | 85mA Max | 16000±3000 | DC2.5-3.8V |

| LBM0518 | φ5*1.8mm | 3.0V DC | 85mA Max | 16000±3000 | DC2.5-3.8V |

| LBM0520 | φ5*2.0mm | 3.0V DC | 85mA Max | 16000±3000 | DC2.5-3.8V |

Ready to Test Our Quality?

Customization Options for Our Smallest BLDC Motors

Structure

Vibration Direction

Our brushless motors can be customized to various sizes to meet your space constraints and performance needs. At present, our existing size is dia 5mm-10mm.

We can meet various design modifications. No matter whether you need lead wire type or FPCB type. Our design team works with you to ensure the motor integrates perfectly with your system and meets functional requirements.

We can add the printing code required by your company on the motor. We use precise printing techniques to ensure your code is prominently displayed and maintains its quality over time.

Features That Make Our Smallest BLDC Motors Unique

Our mini motors are designed with advanced precision engineering to deliver exceptional performance in a compact size. This ensures reliable operation and efficiency, even in the tightest spaces.

Leveraging cutting-edge technology, our dc micro motors offer high efficiency and low power consumption. This translates to longer battery life and reduced energy costs, making them ideal for energy-sensitive applications.

Our small brushless motors stand the test of time and have no brushes to wear out, minimizing maintenance requirements and extending service life.

We provide extensive customization options to meet specific application needs. This flexibility ensures that our smallest brushless motors can be tailored to fit seamlessly into your design and operational requirements.

Applications

Smallest BLDC vibration motors have become indispensable core components across diverse industries, thanks to their compact size (down to φ5mm), high efficiency, long lifespan, and precise vibration control. These motors excel in delivering reliable haptic feedback and stable oscillating performance, making them ideal for space-constrained, energy-sensitive, and high-performance-demanding applications—from consumer electronics to medical devices.

The smallest brushless motors are widely adopted in smartphones, smartwatches, and fitness trackers to provide haptic feedback. For instance, they simulate physical button clicks (replacing traditional mechanical keys), alert users to notifications, or enhance gaming experiences with real-time vibration responses. Their small BLDC design ensures minimal space occupation (fitting into ultra-thin device bodies) and low power consumption, extending battery life—critical for portable electronics.

High-performance micro BLDC vibration motors power premium electric toothbrushes, delivering consistent high-frequency vibrations (or precise oscillating motions) to break down plaque effectively. Unlike brushed motors, small BLDC motors offer longer service life (reducing replacement needs) and quieter operation, enhancing user comfort. They also find use in mini massagers (e.g., facial rollers, handheld muscle massagers), where their compact size and adjustable vibration intensity enable targeted, gentle stimulation.

In the medical field, micro brushless motors are integrated into small-scale devices such as portable blood glucose monitors (providing subtle vibration alerts for test results) and miniaturized therapeutic devices (e.g., vibration-based pain relief tools). Their BLDC technology ensures sterile compatibility (no brush wear to generate debris) and reliable performance under strict operating conditions, while their compact form allows integration into handheld or wearable medical equipment—supporting on-the-go patient care.

Micro BLDC vibration motors play a key role in industrial IoT (IIoT) devices, such as smart sensors for equipment condition monitoring—where they generate calibrated vibrations to test sensor responsiveness or alert maintenance teams to machinery faults. They also power mini actuators in compact industrial tools (e.g., precision dispensing devices), leveraging their precise vibration control to ensure accurate, repeatable operations. Their high efficiency and durability make them suitable for long-term, continuous-use industrial environments.

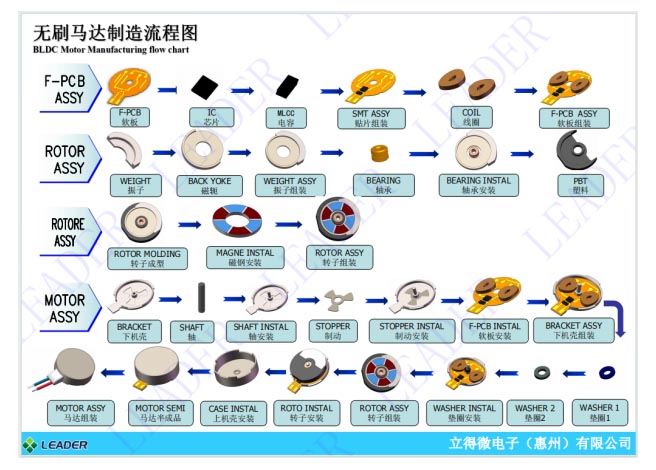

Smallest BLDC Motor Manufacturing Process

We begin with a detailed design phase, where our team collaborates with you to develop precise prototypes. Utilizing advanced CAD software and 3D modeling, we refine the motor’s design to meet specific requirements before moving to production.

High-quality materials are selected for each component of the BLDC motor to ensure durability and performance. We use advanced materials such as high-grade metals and composites that enhance the motor's efficiency and longevity.

Our state-of-the-art manufacturing facilities employ precision machinery to fabricate each component of the motor. This ensures exact dimensions and tolerances, critical for maintaining performance in our mini brushless motors.

Components are meticulously assembled using automated and manual processes to ensure high accuracy and reliability. Each motor undergoes rigorous testing during assembly to verify its functionality and adherence to specifications.

We implement stringent quality control procedures throughout the manufacturing process. Each motor is subjected to thorough testing and inspections to ensure it meets our high standards and performs reliably under various conditions.

After assembly, we integrate any requested custom features. The final product is carefully inspected and prepared for delivery, ensuring it meets all customization and quality require

Get Smallest Bldc Motors in Bulk Step-by-step

Common Customer Questions About the Smallest BLDC Motors

Our smallest BLDC motors offer key advantages such as compact size, high efficiency, and low power consumption. They are ideal for applications where space is limited.

The maximum power output of our micro bldc motors are less than 0.5w. Generally, they are designed to provide optimal performance within a compact form factor, suitable for a range of low power applications.

Yes, we offer extensive customization options, including soldering type and performance specifications. We work closely with you to tailor the motors to your specific application needs, ensuring they fit seamlessly into your design.

Our brushless vibration motors feature a brushless structure and can last over 500,000 cycles (with a 1s on and 1s off operating pattern). We also provide a full set of lifespan test reports for your reference.

We implement rigorous quality control processes throughout the manufacturing process, including material inspections, precision assembly, and extensive testing. Each motor undergoes thorough checks to ensure it meets our high standards and performs reliably. 100% inspection before shipment.

Lead times depend on the complexity of the order and customization requirements. Generally, production and delivery take 2-4 weeks from the confirmation of your order. We provide regular updates to keep you informed about the progress of your order.

Yes, we have OEM/ODM customization capabilities. We can meet your specific requirements for voltage, wire length, and interfaces to ensure the motor fits your application perfectly.

Absolutely. Our brushless vibration motors adopt a low-power design and are 20 - 30% more efficient than brushed motors, which helps extend the battery life of your devices.

Please contact our sales team for specific sample policies. We will try our best to support your evaluation needs before a bulk purchase.

Our brushless vibration motors have obtained global certifications such as ISO and RoHS, ensuring safety and compliance for use in markets worldwide.