3V SMT Motors Manufacturer & Custom Supplier

Main Features

Specification

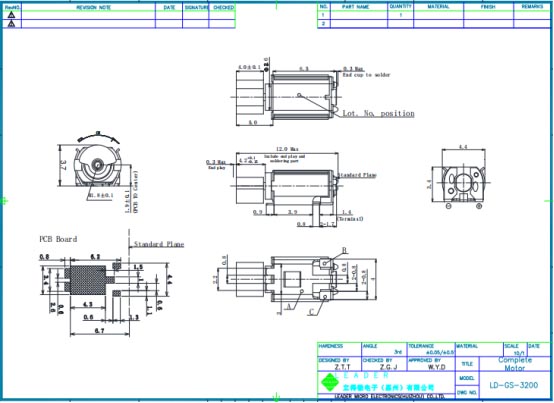

| Technology Type: | BRUSH |

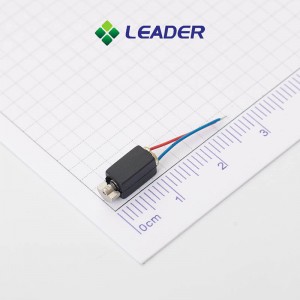

| Diameter (mm): | 4.0 |

| Body Length (mm): | 12 |

| Rated Voltage (Vdc): | 3.0 |

| Operating Voltage (Vdc): | 2.3-3.6 |

| Rated speed (RPM): | 12000±3000 |

| Rated Current(mA MAX): | 85 |

| Rotation: | CW |

| Vibration force (reference): | 0.4G with 100g Jig |

| Mechanical noise: | 45dB Max |

| Qty per reel / tray: | 1000 |

| Quantity - Master box: | 4000 |

Application

The main applications of SMT motor are mobile phone, bracelet, smart watches and so on.

Working with Us

SMT Vibration Motor Manufacturer

As a professional SMT Vibration Motor producer, we take pride in being a source factory with remarkable strengths:

- 100% Self-Manufacture

We are the genuine source factory of 3V SMT motors. We support customizing dimensions, voltage, lead wire methods, and other specifications. Whether you need standard-spec products or personalized 3V SMT motors and custom SMT motor solutions, we can meet your demands.

- Support Small-Batch Sampling

For surface mount motor projects, especially in the early testing stage, we offer fast sampling service. It helps you quickly verify product performance and accelerate project progress, perfectly adapting to the needs of early-stage project testing for 3V SMT motors and other products.

- Rich Export Experience

Our customers of SMT vibration motors are spread across Europe, America, Japan, and South Korea. We are well-versed in various international certification standards such as RoHS and CE. When you choose our custom SMT motor or other SMT vibration motor products for export, there’s no need to worry about certification issues.

- Strict Quality Control

For every batch of SMT vibration motors, before shipment, we conduct a full inspection. We provide test reports and support third-party factory audits. This ensures that the SMT vibration motor products you receive are of high quality.

As a professional micro Vibration motor manufacturer and supplier in China, we can meet customers' needs with custom high quality brushless motor. If you are interested, welcome to contact Leader Micro.

Q1: What are the benefits of using a 3V SMT motor?

A: Compact size, low power consumption, and surface mount compatibility make it ideal for space-constrained, battery-powered devices.

Q2: Can you customize the wire length or connector type?

A: Yes, as a factory we support full OEM/ODM customization based on your PCB design.

Q3: Do your SMT motors meet RoHS or CE standards?

A: Yes, all models comply with international certifications and come with full documentation.

Q4: How does the lifespan of your 3V SMT motors compare to industry averages?

A: Our 3V SMT motors are engineered for durability. With advanced materials and strict quality control, their lifespan exceeds industry averages. For specific lifecycle data on surface mount motors, please contact our team for detailed specifications.

Q5: Are your SMT vibration motors suitable for high-temperature environments?

A: Yes. Our SMT vibration motors undergo high-temp resistance testing. Whether for industrial devices or special-use wearables, they maintain stable performance. For extreme-condition custom SMT motor needs, we can further optimize.

Q6: What’s the lead time for a custom SMT motor order?

A: For custom SMT motor projects (like unique-spec 3V SMT motors ), lead time depends on complexity. Typically, after design confirmation, it takes about 20 business days. We prioritize efficiency while ensuring quality for every SMT vibration motor customization.

Q7: Can surface mount motors work with automated assembly lines smoothly?

A: Absolutely. Our surface mount motors are designed for seamless integration with automated SMT assembly processes. From standard to custom SMT motor models, they meet pick – and – place equipment compatibility, boosting production efficiency.

Q8: Do you offer technical support for integrating custom SMT motors into new products?

A: Yes! For custom SMT motor development, our engineers provide end-to-end support—from initial design advice to post-integration troubleshooting, ensuring your surface mount motor-based products launch successfully.

Industry-Specific Solutions for SMT Vibration Motors

When it comes to industries relying on precise motion components like ours, pain points often arise. But we, as a professional SMT Vibration Motor producer, have tailored solutions.

For the medical field, our 3V SMT motor for medical is a game-changer. Medical devices demand high precision, reliability, and miniaturization. Our motors meet these needs flawlessly. Whether it’s for a portable medical diagnostic tool or a wearable health-monitoring device, the 3V SMT motor for medical ensures stable and accurate vibration, aiding in functions like precise fluid pumping in micro-medical systems or subtle haptic feedback for patient alerts.

In the wearable tech sector, our wearable SMT motor solves key pain points. Wearable devices need components that are ultra-small, energy-efficient, and durable. Our wearable SMT motor fits right in. It provides the necessary vibration for smartwatches‘ haptic notifications, fitness trackers‘ feedback, etc. We understand the constraints of limited space and strict power budgets in wearable designs. That’s why our motors are optimized for small form factors and low power consumption, ensuring they don’t weigh down or drain the battery of your wearable products.

No matter if you’re developing cutting-edge medical equipment with the 3V SMT motor for medical or trendy wearable gadgets using our wearable SMT motor, we’ve got the solutions to overcome industry pain points, delivering performance, reliability, and efficiency.

Case Study: A Leading Education Technology Enterprise’s Use of Our 3V SMT Motor

We are pleased to present a successful application case where our 3V SMT motor has been adopted by a prominent enterprise in the education technology sector. This forward – thinking company, dedicated to developing cutting – edge educational tools, was in search of a motor solution that could meet the high standards of their innovative products.

After careful consideration and comparison of multiple alternatives, they selected our 3V SMT motor. The exceptional precision and reliable performance of our SMT vibration motor, which is a key type of 3V SMT motors, were the main reasons behind their choice. Our surface mount motor’s compact design allows for easy integration into their intricate device structures, and its low power consumption is in line with their pursuit of energy – efficient products.

In their specific product development, our custom SMT motor proved to be an ideal fit. It played a vital role in enabling accurate tactile feedback in interactive learning devices and ensuring stable operation in portable educational equipment. The successful application of our 3V SMT motor in their products demonstrates the versatility and quality of our offerings. It serves as a strong proof that our 3V SMT motors, SMT vibration motors, surface mount motors, and custom SMT motor solutions can effectively support the development of advanced educational technology products, providing potential clients with a reliable reference for their own projects.

Quality Control

We have 200% inspection before shipment and the company enforces quality management methods, SPC, 8D report for defective products. Our company has a strict quality control procedure, which mainly tests four contents as follow:

01. Performance Testing; 02. Waveform Testing; 03. Noise Testing; 04. Appearance Testing.

Company Profile

Established in 2007, Leader Micro Electronics (Huizhou) Co., Ltd. is a high-tech enterprise integrating R&D, production, and sales of micro vibration motors. Leader mainly manufactures coin motors, linear motors, brushless motors and cylindrical motors, covering an area of more than 20,000 square meters. And the annual capacity of micro motors is nearly 80 million. Since its founding, Leader has sold nearly a billion of vibration motors all over the world, which are widely used on about 100 kinds of products in different fields. The main applications conclude smartphones, wearable devices, electronic cigarettes and so on.

Reliability Test

Leader Micro has professional laboratories with a full set of testing equipment. The main reliability testing machines are as below:

01. Life Test; 02. Temperature & Humidity Test; 03. Vibration Test; 04. Roll Drop Test;05. Salt Spray Test; 06. Simulation Transport Test.

Packaging & Shipping

We support air freight, sea freight and express.The main express are DHL, FedEx, UPS, EMS, TNT etc. For the packaging: 100pcs motors in a plastic tray >> 10 plastic trays in a vacuum bag >> 10 vacuum bags in a carton.

Besides, we can provide free samples on request.