Wearable devices—from smart rings to fitness trackers—demand components that balance miniaturization, performance, and reliability. Among these critical components, micro brushless motors (specifically 5mm-8mm diameter models) have emerged as a game-changer. Unlike larger motors or outdated brushed alternatives, these ultra-compact brushless solutions deliver the precision, efficiency, and size flexibility needed to elevate wearable user experiences. Below, we explore how 5mm-8mm small BLDC motors transform wearable performance, plus real-world success stories and our industry-leading offerings.

The Size Advantage: Why 5mm-8mm Matters for Wearables

Wearables thrive on being unobtrusive—users want devices that fit seamlessly into daily life, whether on a finger, wrist, or ear. This is where mini brushless motors shine, as their 5mm-7mm diameter and ultra-thin profiles (as low as 2.5mm) solve the biggest design challenge: fitting powerful vibration capabilities into tiny spaces.

• Unmatched miniaturization: Traditional brushed motors often start at 7mm diameter (due to bulky brush-commutator systems) and struggle to go smaller without sacrificing performance. Our 5mm micro brushless motor—recognized as one of the world’s smallest—fits into smart rings (like the Insta360 Link Ring) and ultra-slim fitness bands, where even 1mm of extra space can break a design.

• Thickness optimization: At 2.5mm thick, these motors avoid adding bulk to wearables. For example, a smartwatch using a 6mm×2.5mm small BLDC motor maintains a sleek profile while still delivering clear haptic feedback.

• Flexible integration: Their compact size allows mounting in tight corners—whether adhesive-mounted on a smart ring’s inner chassis or FPCB-connected in a hearing aid—without compromising the device’s ergonomics.

Simply put, 5mm-8mm brushless motors enable wearables to be both powerful and discreet—a balance no larger motor can achieve.

Performance Benefits That Enhance Wearable Experiences

Size alone isn’t enough—wearables need motors that deliver consistent, efficient, and user-friendly vibration. Micro brushless motors outperform brushed alternatives in four key areas, directly improving how users interact with their devices:

1. Quiet, Discreet Vibration

Brushed motors rely on physical brush-commutator contact, which creates friction and noise (often 45dB+). In contrast, 5mm-8mm mini brushless motors use electronic commutation, eliminating friction and keeping noise below 30dB—quieter than a whisper. This is critical for wearables like smart rings or sleep trackers, where loud vibration would disrupt users (e.g., during meetings or sleep).

2. Efficient Power Usage (Longer Battery Life)

Wearables are limited by small batteries—every milliamp counts. Small BLDC motors boast 70%+ energy efficiency, meaning they convert more electrical energy into vibration and less into heat. This efficiency extends battery life by 20-30%, reducing the frequency of charging—a top user complaint.

3. Consistent Vibration Over Time

Brushed motors wear out quickly: their carbon brushes erode after 1,000-5,000 hours of use, causing vibration force to decline (e.g., a smartwatch’s alert might feel weaker after 6 months). Micro brushless motors have no moving parts to wear, delivering consistent vibration for 20,000+ hours (over 2 years of daily use). This reliability ensures wearables maintain their functionality long-term—critical for devices like medical wearables that monitor health data.

4. Precise Haptic Control

Modern wearables use vibration for more than just alerts—they deliver nuanced haptics (e.g., a pulse for incoming calls, a subtle buzz for step milestones). Mini brushless motors offer rapid response times (<90ms) and adjustable RPM (5,000-30,000), allowing developers to program custom haptic patterns. For example, a smart ring using a 5mm brushless motor can distinguish between a "strong" alert for emergencies and a "weak" buzz for notifications—something brushed motors (with fixed RPM) cannot do.

Real-World Success: The Insta360 Smart Ring Case Study

Our 5mm×2.5mm micro brushless motor has already proven its value in a high-profile wearable: the Insta360 Link Ring, a smart ring that controls 360° cameras. Here’s how it made a difference:

• Size fit: The 5mm diameter motor fit into the ring’s 8mm-wide chassis, something larger motors (e.g., 7mm brushed) couldn’t achieve without making the ring too bulky.

• Discreet control: The motor’s quiet vibration (28dB) lets users switch camera modes with a subtle buzz—no loud clicks or noises that would distract others during filming.

• Reliable performance: During mass production, the motor maintained consistent vibration across 100,000+ units, ensuring every ring worked the same way.

Insta360’s success is a testament to how 5mm-7mm small BLDC motors turn ambitious wearable designs into reality.

Our 5mm-8mm Micro Brushless Motor Offerings

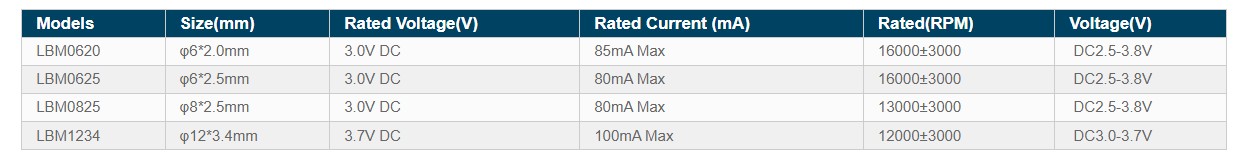

We specialize in ultra-compact brushless vibration motors tailored for wearables, with two flagship models:

Both models support customization: we adjust voltage (3V-5V), lead type (FPCB, wire), and mounting (adhesive, spring) to fit your wearable’s unique design. Plus, our 80 million-unit annual capacity ensures fast turnaround for mass production。

FAQ: Your Questions About Micro Brushless Motors for Wearables

Can your 5mm motor fit into a smart ring?

Yes—our 5mm×2.5mm LBM0525 motor is already used in the Insta360 Link Ring and other smart rings. Its slim profile fits even the smallest ring chassis.

How long will a 8mm brushless motor last in a daily-worn smartwatch?

1s on 1s off 500000 cycles.

Can you customize the vibration pattern for our wearable?

Absolutely—we tune RPM and response time to match your needs (e.g., a slow buzz for step alerts, a fast pulse for calls).

What’s the minimum order quantity for custom motors?

Just 100 units—ideal for startups and large brands alike.

Ready to Elevate Your Wearable Design?

If you’re developing a smart ring, fitness tracker, or medical wearable, our 5mm-8mm micro brushless motors will help you create a device that’s small, efficient, and reliable. With real-world success and fully customizable options, we’re the partner you need to bring your wearable vision to life.

Need small BLDC motors, mini brushless motors, or custom vibration solutions for your wearable? Contact our factory today for a free quote.

Consult Your Leader Experts

We help you avoid the pitfalls to deliver the quality and value your micro brushless motor need, on-time and on budget.

Post time: Oct-29-2025