I. How to Install a Small Vibration Motor on a Smart Phone /IQOS e-Cigarette?

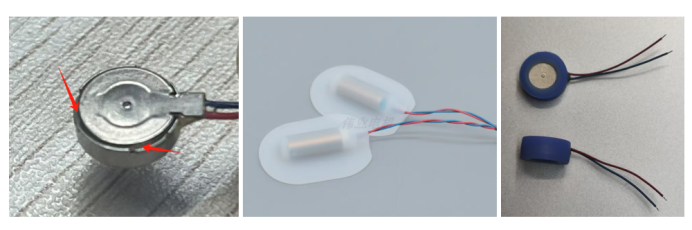

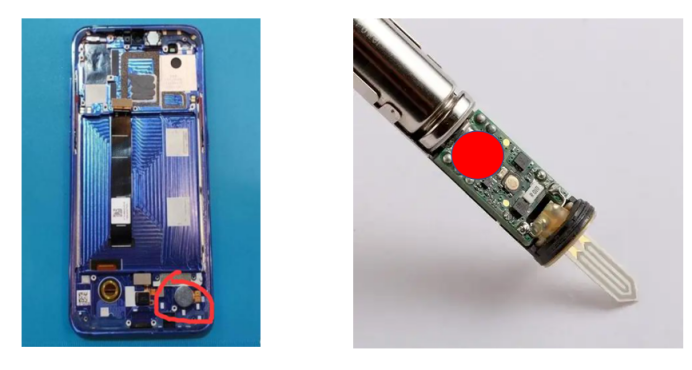

For smart phone types, it is recommended to install vibration motor at the bottom of the phone.

It is not recommended to install it at the top. Because there are some important core components such as cameras, chips and antennas.

It is not recommended to install it in the middle as there is no significant vibration sensation at the bottom.

1.2 It is recommended that e-cigarettes be installed in the middle of the cigarette pole, avoiding the heating components.

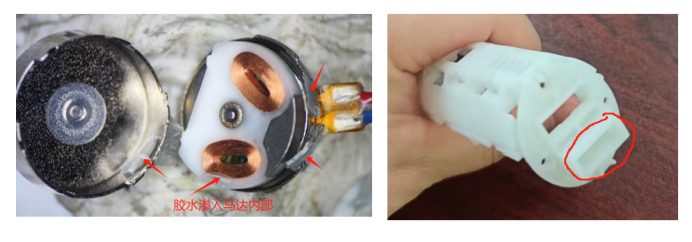

II. Can glue be applied around the small vibration motor to fix it?

Adverse effects: Dispensing glue around the motor can easily cause the glue to seep into the motor interior. After the glue bonds and hardens, it will block the normal operation of the micro dc motor in the form of foreign substances (for details, see the left picture below).

Alternative suggestion: Add installation slots. If there is a slight interference in the height direction of the motor, apply high-adhesive double-sided tape (3M or SONY T4000) to the upper and lower casing of the motor. For more details, please consult the LEADER technical department.

Iii. Can the micro vibration motor be waterproof?

The micro vibration motor is not waterproof.

The reason is determined by the motor's production process. As the upper and lower casing of the motor fit loosely, there is a gap at the junction, making it easy for water to enter.

Suggestion: Add a silicone sleeve to the lower casing of the motor.

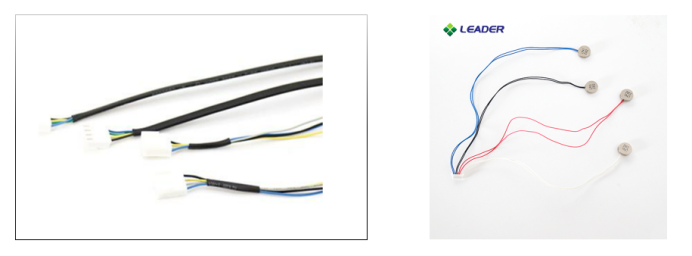

Iv. Heat Shrink Tubing and Connectors

Some customers are not familiar with small dc motors and use heat shrink tubes during installation.

What are the disadvantages of this method? Can connectors be used as substitutes?

(1) No: The shrinkage temperature of heat shrink tubes is generally 84℃ to 120℃, and they cannot be directly used in brushed dc motors. If the motor wire is wrapped in heat shrink tubing, we cannot separate the wire during soldering, which will affect the operation of the soldering motor. It is not recommended to use heat shrink tubing.

(2) Alternative solution: It can be suggested that the customer use a connector.

Consult Your Leader Experts

We help you avoid the pitfalls to deliver the quality and value your micro brushless motor need, on-time and on budget.

Post time: May-17-2025