In the realm of vibration - producing components, two prominent options stand out: 3V SMT motors and traditional vibration motors. Each has its own set of characteristics, advantages, and limitations that make them suitable for different applications. This article aims to provide a comprehensive comparison between 3V SMT motors and traditional vibration motors, helping you make an informed decision based on your specific needs.

Size and Space Efficiency

3V SMT Motors

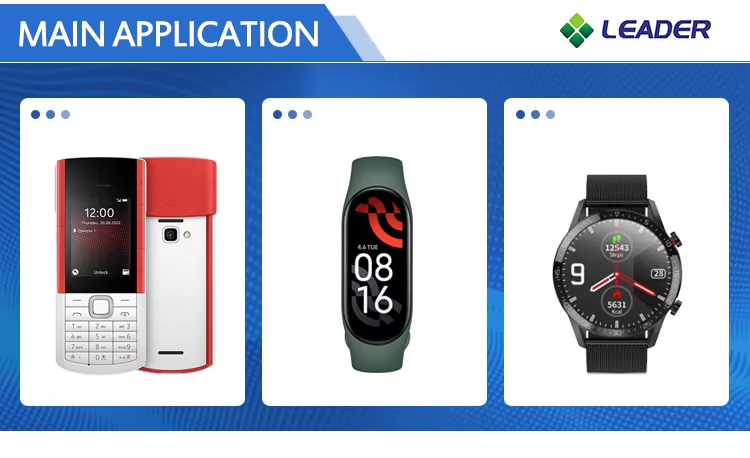

3V SMT motors are designed with compactness in mind, which is a key advantage in modern electronic devices, especially wearables and small - scale gadgets. Their surface - mount technology allows them to be directly mounted on the circuit board, eliminating the need for additional space - consuming mounting structures. For example, many 3V SMT motors have a diameter as small as 4.0 mm and a body length of around 12 mm, making them ideal for devices where space is at a premium. This small size enables seamless integration into smartwatches, fitness trackers, and other miniaturized electronics without adding significant bulk.

Traditional Vibration Motors

Traditional vibration motors, on the other hand, are generally larger in size. They often come with leads or pins for connection, which require extra space on the circuit board and in the device enclosure. Their bulkier design makes them less suitable for compact devices. For instance, some traditional motors may have a diameter of 10 mm or more and a longer body, taking up valuable space that could be used for other components or to make the device more portable.

Power Consumption

3V SMT Motors

As the name suggests, 3V SMT motors operate at a low voltage of 3V, which translates to low power consumption. This is a crucial factor for battery - powered devices, as it helps extend the battery life. These motors are engineered to be energy - efficient, ensuring that they consume minimal power while delivering the required vibration output. For example, a 3V SMT motor used in a fitness tracker can provide vibration alerts for incoming calls or workout reminders without draining the battery too quickly, allowing the device to run for longer periods between charges.

Traditional Vibration Motors

Traditional vibration motors typically operate at higher voltages, such as 6V or 12V, which means they consume more power. This higher power consumption can be a drawback in battery - powered devices, as it leads to more frequent recharging or battery replacement. For devices that are not reliant on batteries, this may not be a major issue, but for portable electronics, the power efficiency of 3V SMT motors gives them a clear edge.

Installation and Integration

3V SMT Motors

The surface - mount technology of 3V SMT motors simplifies the installation process. They are designed to be handled by automated pick - and - place machines, which allows for efficient and precise assembly onto the circuit board. This not only reduces the time and cost of manufacturing but also ensures a more reliable connection. During the reflow soldering process, the motors are securely attached to the board, minimizing the risk of loose connections. Additionally, their small size and direct mounting make them easy to integrate into the overall design of the device without causing significant disruptions.

Traditional Vibration Motors

Traditional vibration motors usually require through - hole mounting, which is a more labor - intensive process. The leads or pins of the motor need to be inserted into holes on the circuit board and then soldered manually or using wave soldering. This process is slower and more prone to errors, such as cold solder joints, which can affect the performance of the motor. Moreover, the additional space required for the leads and mounting can complicate the design of the device.

Performance Characteristics

3V SMT Motors

3V SMT motors offer excellent vibration performance with quick response times. They can start and stop vibrating almost instantly, making them suitable for applications where precise and timely vibration alerts are needed. The vibration strength of these motors can be adjusted to meet specific requirements, ranging from gentle vibrations for subtle notifications to stronger vibrations for more urgent alerts. Their small size also means that the vibration is localized, reducing the impact on other components of the device.

Traditional Vibration Motors

Traditional vibration motors are known for their higher vibration amplitudes, which can be beneficial in applications where a more powerful vibration is required, such as in industrial equipment or large - scale devices. However, their response times are generally slower compared to 3V SMT motors, which can be a disadvantage in applications that demand rapid vibration changes. Additionally, the larger size of traditional motors can cause more widespread vibration in the device, potentially affecting the performance of other components.

FAQ

Are 3V SMT motors more expensive than traditional vibration motors?

The cost of 3V SMT motors and traditional vibration motors can vary depending on factors such as the manufacturer, specifications, and order quantity. In general, 3V SMT motors may have a slightly higher initial cost due to their advanced manufacturing process and compact design. However, when considering the overall cost of production, including installation and assembly, 3V SMT motors can often be more cost - effective. Their automated installation reduces labor costs, and their small size can save on material and packaging costs.

Can 3V SMT motors replace traditional vibration motors in all applications?

While 3V SMT motors offer many advantages, they may not be suitable for all applications. Traditional vibration motors are better suited for applications that require high vibration amplitudes or operate at higher voltages. For example, in industrial machinery where a strong vibration is needed to shake loose materials, a traditional motor may be a better choice. On the other hand, 3V SMT motors are ideal for small, battery - powered devices such as wearables, smartphones, and portable electronics.

How do 3V SMT motors and traditional vibration motors differ in terms of durability?

Both 3V SMT motors and traditional vibration motors can be durable if they are of high quality and used within their specified operating conditions. 3V SMT motors, due to their compact design and lack of external leads, are less prone to physical damage from handling or vibration during operation. However, they may be more sensitive to extreme temperatures and humidity if not properly protected. Traditional vibration motors, with their sturdier construction and larger size, can often withstand harsher environmental conditions but are more susceptible to damage from lead bending or loose connections.

Need 3v SMT Motors? Contact our factory today for a free quote.

Lisa / leader@leader-cn.cn

Consult Your Leader Experts

We help you avoid the pitfalls to deliver the quality and value your micro brushless motor need, on-time and on budget.

Post time: Aug-01-2025