Linear Resonant Actuators (LRAs) have become indispensable components in modern electronic devices, powering the haptic feedback we feel in smartphones, wearables, gaming controllers, and more. Unlike traditional eccentric rotating mass (ERM) motors that rely on spinning weights, LRAs operate on the principle of resonant vibration, delivering precise, efficient, and customizable tactile sensations. Below is a detailed breakdown of how LRAs work, their core components, and the physics that drive their performance.

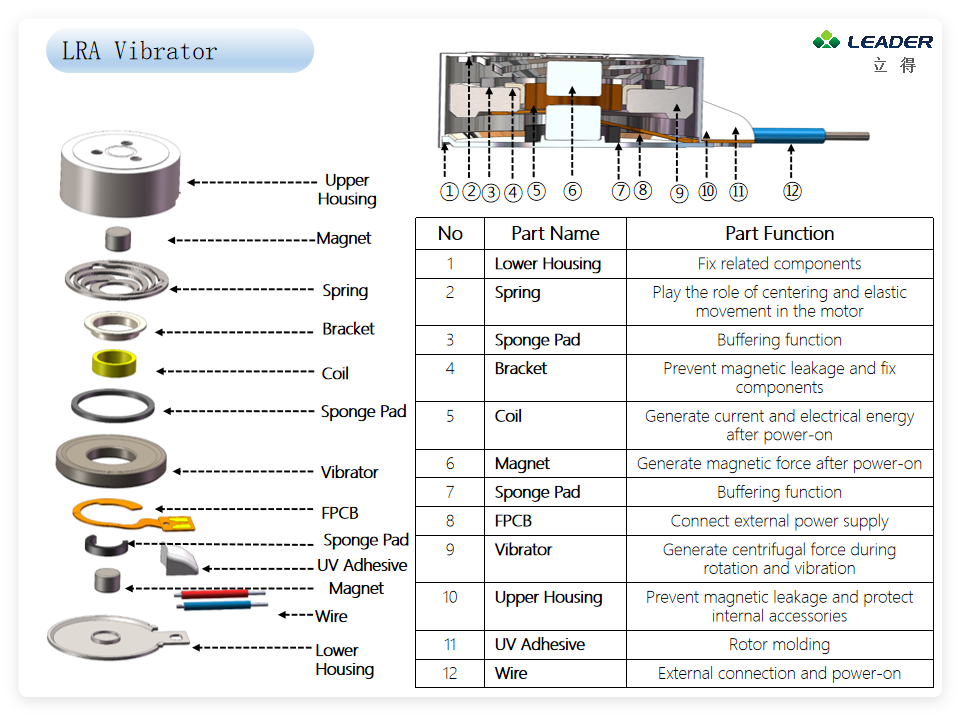

Core Components of a Linear Resonant Actuator

To understand an LRA’s operation, it’s first essential to examine its key parts, each designed to enable resonant motion:

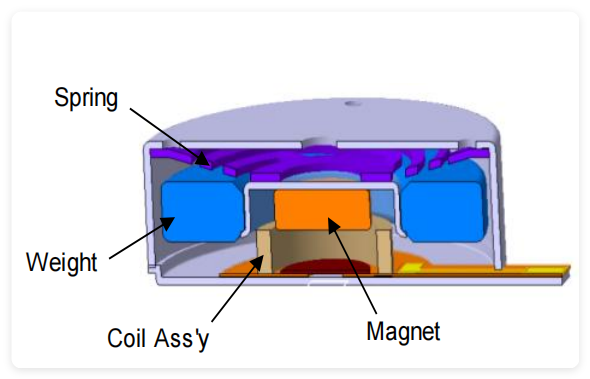

Magnet Assembly: Typically a permanent magnet (often neodymium for high magnetic flux density), this component forms the moving mass of the LRA. It is suspended within the device, allowing it to oscillate back and forth along a single linear axis.

Coil: A stationary electromagnetic coil surrounds the magnet assembly. When an electrical current flows through the coil, it generates a magnetic field that interacts with the permanent magnet’s field—this interaction is the driving force behind the LRA’s motion.

Suspension System: Composed of flexible springs (often made of metal or polymer), the suspension system holds the magnet in place while enabling smooth linear movement. It also plays a critical role in defining the LRA’s resonant frequency, as the spring’s stiffness and the magnet’s mass determine the natural frequency at which the system vibrates most efficiently.

Housing: A rigid outer casing encases all components, providing structural support and ensuring that the oscillating motion is transmitted effectively to the device (and ultimately to the user’s touch).

The Fundamental Working Principle: Resonance and Electromagnetic Interaction

LRA motor operate based on two key physical phenomena: electromagnetic force and mechanical resonance. Here’s a step-by-step breakdown of the process:

Electromagnetic Force Generation: When a voltage is applied to the LRA’s coil, an alternating current (AC) flows through it. According to Ampère’s law, this current creates a time-varying magnetic field around the coil. The direction of this magnetic field switches with the polarity of the AC signal (e.g., positive current creates a north pole at one end of the coil, while negative current reverses it to a south pole).

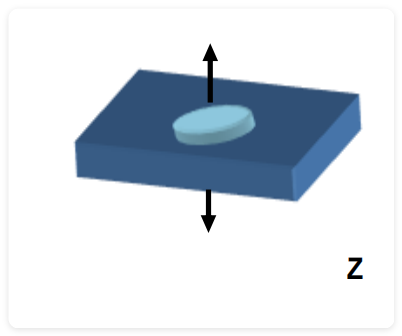

Magnetic Interaction and Motion: The permanent magnet inside the LRA is polarized (with north and south poles), so it experiences a force when exposed to the coil’s alternating magnetic field. When the coil’s magnetic field aligns with the magnet’s poles, the magnet is pulled toward the coil; when the field reverses, the magnet is pushed away. This back-and-forth force causes the magnet to oscillate linearly along its axis.

Resonance: Maximizing Efficiency and Amplitude: The linear motor is designed to operate at its mechanical resonant frequency—the natural frequency at which the suspension system and magnet mass vibrate with minimal energy input. At resonance, the system’s impedance is minimized, meaning most of the electrical energy supplied to the coil is converted into mechanical vibration (rather than being lost as heat). This results in larger vibration amplitudes and higher efficiency compared to non-resonant operation. For example, a typical smartphone LRA has a resonant frequency between 100–200 Hz, which is optimized for human tactile perception.

Damping and Control: While resonance boosts efficiency, it also requires precise control to avoid unstable vibrations. Most LRA motors are paired with dedicated drivers (such as Texas Instruments’ DRV2605 or DRV2625) that regulate the AC signal’s frequency and amplitude. These drivers ensure the LRA operates exactly at its resonant frequency (compensating for manufacturing variations or temperature changes) and allow for adjustable vibration intensity—from subtle taps (e.g., notification alerts) to strong pulses (e.g., gaming feedback).

Key Advantages of LRAs Over Other Haptic Technologies

The resonant operating principle gives LRAs several distinct benefits that make them ideal for consumer electronics:

Precision: LRAs vibrate along a single linear axis, producing consistent, predictable tactile feedback without the rotational “rumble” of ERM motors. This makes them perfect for applications requiring nuanced sensations, such as touchscreen haptics or virtual button presses.

Efficiency: By leveraging resonance, LRAs consume less power than ERMs for the same vibration amplitude. This is critical for battery-powered devices like smartphones and wearables, where energy efficiency is a top priority.

Compact Size: LRAs have a slim, flat design (often just a few millimeters thick) that fits easily into tight device enclosures. Their linear motion also eliminates the need for rotating parts, reducing overall size and weight.

Fast Response Time: The lightweight magnet and low-inertia design of LRAs allow them to start and stop vibrating almost instantly. This enables rapid, sequential feedback (e.g., typing on a virtual keyboard) that feels natural and responsive.

Real-World Applications

LRAs are ubiquitous in modern technology, enhancing user experiences across industries:

Consumer Electronics: Smartphones (e.g., haptic feedback for typing, navigation, or gaming), smartwatches (e.g., vibration alerts for calls or fitness milestones), and tablets.

Gaming: Controllers for consoles and mobile games, where precise haptics (e.g., simulating impacts, terrain, or weapon recoil) immerse players in the gameplay.

Automotive: Touchscreens and infotainment systems in cars, providing tactile confirmation for button presses to reduce driver distraction.

Wearables and Medical Devices: Fitness trackers, hearing aids, and medical monitors, where discrete vibrations deliver important alerts without audio.

Conclusion

Linear Resonant Actuators revolutionize haptic feedback by combining electromagnetic technology with mechanical resonance, delivering efficient, precise, and compact vibration solutions. By understanding their core components—magnet, coil, suspension, and housing—and the physics of resonant motion, we can appreciate why LRAs have become the go-to choice for engineers designing next-generation tactile experiences. Whether you’re typing a text, playing a game, or navigating a smart device, the smooth, responsive vibration you feel is likely powered by the elegant working principle of a linear resonant actuator.

Consult Your Leader Experts

We help you avoid the pitfalls to deliver the quality and value your micro brushless motor need, on-time and on budget.

Post time: Dec-16-2025