Micro Brushless Motor Manufacturer

A micro brushless motor is a small-sized electric motor that uses brushless technology for propulsion. The motor comprises a stator and a rotor with permanent magnets attached on. The absence of brushes eliminates the friction, resulting in greater efficiency, longer lifespan and quieter operation.A micro brushless motor typically measures less than 6mm in diameter, making it an excellent choice for tiny devices:Especially robots, wearable devices and other micro-mechanical applications where the compact size and high performance are critical.

As a professional micro brushless motor manufacturer and supplier in China, we can meet customers' needs with custom high quality brushless motor. If you are interested, welcome to contact Leader Micro.

What We Produce

Micro brushless motor can achieve very high speeds and provide precise control, but they are also more complex and expensive than brushed motors. Nonetheless, their superior performance and reliability make them the preferred choice for many applications that demand compactness and efficiency.

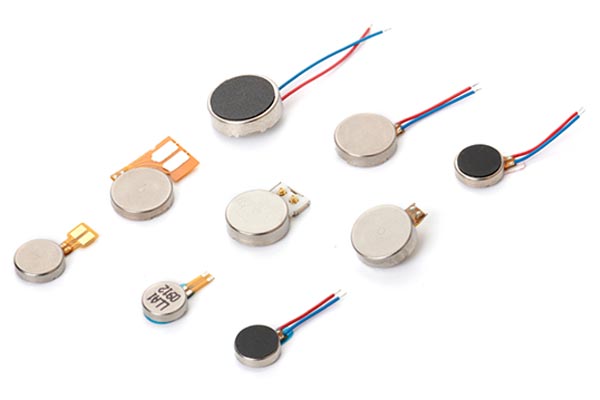

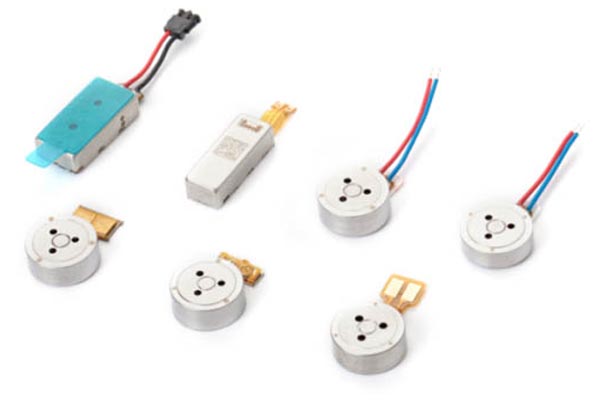

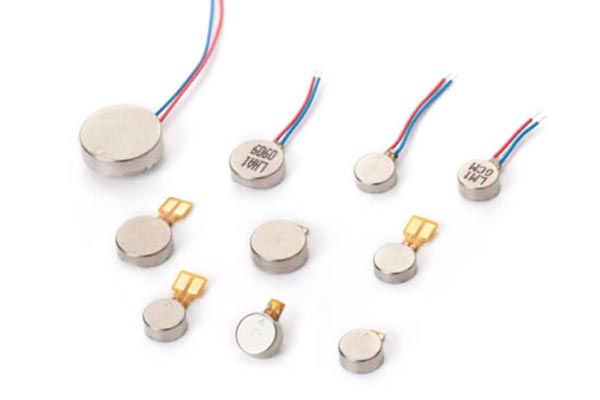

Our company currently offers four models of brushless motors with diameters ranging from 6-12mm. We have different diameter options available to meet the high-speed requirements of various applications. We are constantly improving our brushless motor designs to stay ahead of industry trends and meet the evolving demands of our customers.

Looking for precision and smooth motion? Discover how our linear motors provide unparalleled performance for advanced applications!

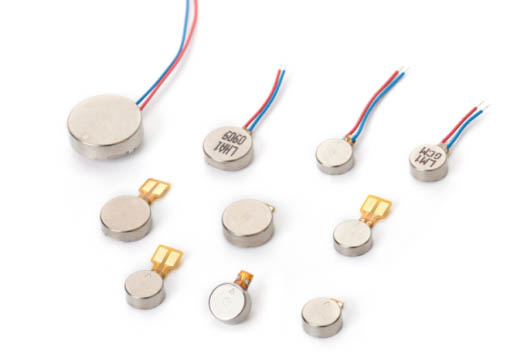

FPCB Type

FPCB (Flexible Printed Circuit Board) type BLDC vibration motors integrate flexible circuits for compact, high-performance actuation.

Structure: Flexible circuit design enables tight spaces fit (wearables, small electronics).

Performance: Brushless operation ensures smooth vibration, efficiency, and long lifespan.

Lead Wire Type

Lead Wire type BLDC vibration motors utilize lead wires for electrical connection, offering versatility in various applications.

Structure: Lead wire design allows for easy integration and wiring flexibility, suitable for devices where spatial layout and connection adaptability are needed.

Performance: Leveraging BLDC technology, they deliver smooth, efficient vibration with extended durability, free from brush-related wear.

General Features: Available in different sizes to match diverse requirements, providing reliable haptic feedback for consumer electronics, industrial equipment, and more.

| Models | Size(mm) | Rated Voltage(V) | Rated Current (mA) | Rated(RPM) | Voltage(V) |

| LBM0525 | φ5*2.5mm | 3.0V DC | 90mA Max | 12000 Min | DC2.7-3.3V |

| LBM0620 | φ6*2.0mm | 3.0V DC | 80mA Max | 12000 Min | DC2.7-3.3V |

| LBM0625 | φ6*2.5mm | 3.0V DC | 80mA Max | 16000±3000 | DC2.7-3.3V |

| LBM0825 | φ8*2.5mm | 3.0V DC | 80mA Max | 13000±3000 | DC2.7-3.3V |

| LBM1234 | φ12*3.4mm | 3.7V DC | 100mA Max | 12000±3000 | DC3.0-3.7V |

Like One of Our Samples? Request It and Start Your Testing Phase Today.

Why Choose LEADER’s Micro Brushless DC Motors?

LEADER’s micro brushless DC motors stand out for:

Our motors (e.g., φ5–12mm sizes) are engineered to fit into the tightest spaces—perfect for wearables, medical implants, or ultra-thin electronics.

We offer tailored designs (FPCB type, lead wire type, etc.) and vibration profiles to meet specific industry needs (e.g., gentle haptics for smartwatches, robust vibration for industrial alerts).

Built with high-grade materials (rare-earth magnets, precision PCBs) and rigorous testing, our motors ensure consistent performance in harsh environments (temperature fluctuations, moisture).

We integrate advanced commutation and control systems, enabling energy-efficient, long-lasting operation—backed by years of expertise in micro motor engineering.

By controlling the entire production process from R&D to manufacturing in-house, we can better manage costs and ensure on-time delivery, helping you avoid delays and budget overruns.

We can meet special requirements for voltage, wire length, and interfaces, allowing your products to be perfectly tailored to unique application scenarios.

Our compliance with international standards like ISO and RoHS ensures safety and regulatory adherence, making your products suitable for markets worldwide without compliance concerns.

Our professional engineers provide selection guidance, helping you pick the right motor quickly and shortening your product development cycle.

Customer Pain Points & Our Solutions

We understand that customers encounter several critical challenges when using vibration motors, and we've developed targeted solutions to address each one, backed by our technological and supply chain strengths.

Traditional vibration motors often have a short service life, and frequent replacements can seriously affect the stability of your products.

Our solution: Leveraging a brushless structure, our brushless vibration motors boast a lifespan exceeding 500,000 cycles (with a 1s on and 1s off operating mode). Moreover, we provide a complete set of lifespan test reports to ensure you can trust the long-term reliability of our motors.

Excessive power consumption of vibration motors can significantly impact the battery life of devices, which is a major concern for many applications.

Our solution: With a low-power design, our brushless vibration motors are 20 - 30% more efficient than brushed motors. This efficiency improvement helps extend the battery life of your products, enhancing the user experience.

Unpredictable lead times and the risk of supply chain disruptions can cause delays and uncertainties in your production plans.

Our solution: We have our own factory, which enables us to guarantee mass production capacity. Additionally, we can quickly carry out small-batch trial production, ensuring a stable supply and timely delivery to meet your production needs.

How Are Micro Brushless Motors from LEADER Designed?

LEADER’s micro brushless motors (like their vibration motor series) are engineered with a focus on miniaturization, performance, and application-specific reliability:

LEADER optimizes the stator-rotor geometry to fit into ultra-small form factors (e.g., diameters as low as 5mm). Materials like high-grade rare-earth magnets and precision-engineered copper windings ensure strong torque despite the small size.

For vibration-specific models, LEADER integrates efficient BLDC control logic into the motor design, enabling precise vibration frequency and intensity control. This is crucial for haptic feedback in wearables or medical devices.

By leveraging brushless technology, these motors minimize friction and wear. LEADER also refines manufacturing processes to ensure consistency—critical for mass deployment in consumer electronics or industrial IoT devices.

Whether for FPCB-type (flexible circuit) or lead-wire-type configurations, LEADER tailors motor designs to meet the spatial and performance needs of specific industries (e.g., ultra-thin profiles for smartwatches, robust builds for medical tools)

As a Direct Manufacturer, We Provide Fast Sample Delivery

Small Brushless Motor Key Feature:

Our motors are engineered to ensure precise and consistent performance, ensuring your application runs smoothly every time.

Our advanced brushless DC motors are designed for optimized power use, allowing you to benefit from superior energy efficiency and lower operating costs.

Our motors stand the test of time and have no brushes to wear out, minimizing maintenance requirements and extending service life.

Enjoy ultra-quiet motor operation, ideal for noise-sensitive environments, providing a tranquil atmosphere without compromising performance.

From robotics to renewable energy solutions, our motors have proven their performance in diverse applications, demonstrating unparalleled versatility.

Our brushless DC motors achieve higher efficiency levels by eliminating friction caused by brushes in traditional motors, resulting in less heat generation and longer motor life.

Our motors are smaller and lighter, making them ideal for applications where space and weight constraints are important considerations, delivering maximum performance in limited space.

Application

Small brushless motors are generally smaller and more efficient than brushed motors. The BLDC coin vibration motor is slightly more expensive due to the inclusion of a driver IC. When powering these motors, it is critical to pay close attention to polarity (+ and -). Additionally, they are known to last longer, produce less noise, and can be used in a wider range of applications. Including:

BLDC vibration motors are commonly used in massage chairs to provide various massage techniques and relieve muscle tension. These motors produce vibrations of varying intensities and frequencies to stimulate blood circulation and relax the body. They are also used in other personal care products such as hand massagers, foot baths and facial massagers.

BLDC vibration motors are integrated into game controllers to provide tactile feedback, enhancing the gaming experience by providing a sense of touch. They provide vibration and feedback to simulate different in-game events such as collisions, explosions or weapon recoil.

BLDC vibration motors are commonly used in vibrating alarms and pagers to provide discreet and effective notifications for people with hearing impairments. The motor creates vibrations that users can feel, alerting them to incoming calls, messages or alerts. They are also used in vibrating wristbands and sirens for those who have difficulty hearing audible alarms or sirens.

Micro brushless motors are frequently employed in medical devices due to their small size, high efficiency and precise control. Dental drills, surgical instruments and prosthetic devices are medical devices that benefit from these motors. Using 3V micro brushless motors in medical can produce better outcomes for patients, including faster procedures, smoother movements and improved control. By enhancing the precision and efficiency of medical devices, these motors can help to enhance patient comfort and overall outcomes.

Micro brushless motors are commonly used in smartwatches to control the vibration function. They provide precise and reliable haptic feedback, alerting users of incoming notifications, calls or alarms. The micro motors are small, lightweight and consume very little power, making them ideal for use in wearable technology.

Micro brushless motors are often used in beauty devices, such as facial massagers, hair removal devices and electric shavers. These devices rely on the motor's vibration to perform their intended functions. The micromotor's compact size and low noise make them ideal for handheld beauty devices.

Micro brushless motors are extensively used in small robots, drones and other micro-mechanical systems. The motors provide precise and high-speed control, which is essential for these devices to operate efficiently. They are used in various robot applications, such as propulsion, steering and movements.

In summary, micro brushless motors offer precise control, low noise and high efficiency. They are often preferred over traditional brushed motors for their many benefits.

Why Brushless Vibration Motors Outperform Brushed Motors?

Compared to traditional brushed vibration motors, brushless models excel in lifespan, efficiency, and vibration stability—all rooted in their brushless design and driver-controlled operation:

Brushed motors fail primarily due to mechanical wear from brush-commutator contact: As the commutator rotates, metal/carbon brushes rub against it, gradually wearing down. Worn brush particles also clog gaps between commutator segments, leading to short circuits. Brushes may even snap, causing open-circuit failures. Typically, brushed motors last only 100000 cycles (1s on, 1s off).

Brushless motors eliminate brushes and commutators, removing mechanical wear risks. Their core components (coils, magnets, driver IC) have minimal degradation over time, allowing them to operate for 500000 cycles (1s on, 1s off).

Brushed motors waste energy in two key ways:

- Contact resistance: Friction between brushes and the commutator creates electrical resistance, converting part of the input energy into heat (rather than rotational force).

- Arcing loss: When brushes switch between commutator segments, electrical arcs (continuous discharges, unlike short sparks) form, consuming extra energy.

Brushless motors have no contact resistance or arcing. Electrical energy is directly converted into magnetic energy in the stator coils, then into rotational force—minimizing energy waste. This efficiency makes them suitable for battery-powered devices or applications where energy conservation is critical.

Brushed motors produce unstable vibration due to inconsistent current and wear:

- Unstable current supply: Fluctuations in brush-commutator contact gaps (from wear or alignment) cause current to vary, leading to erratic shaft speed and uneven vibration.

- Wear-induced deviation: As brushes wear, their contact area shrinks and resistance increases, worsening current fluctuations and making vibration amplitude/frequency unpredictable.

Brushless motors use the driver IC to precisely control stator power timing, ensuring stable, continuous current supply—the shaft rotates at a uniform speed, and the eccentric mass produces consistent vibration. Without mechanical wear, their performance remains consistent over time, avoiding vibration drift even after thousands of hours of use.

Brushed DC Motors |

Brushless DC Motors |

|

Shorter lifespan |

Longer lifespan |

|

increased louder noise |

Reduced quieter noise |

|

Lower reliability |

Higher reliability |

|

Low cost |

High Cost |

|

Low efficiency |

High efficiency |

|

Commutator sparking |

No sparking |

|

Low RPM |

High RPM |

|

Easy to drive |

Hard to drive |

The lifespan of brushless motor

The lifespan of a micro brushless dc motor is primarily dependent on several factors, such as its build quality, operating conditions and maintenance practices. Generally, brushless motors have a longer lifespan than brushed motors due to their more efficient design, which reduces mechanical wear and tear. It should be noted that the motor must be assembled to the terminal device within six months of shipping date. If the small vibration motor has not been used for more than six months, it is recommended to activate the motor with electricity (powered on for 3-5 seconds) before use to achieve the best vibration effect.

However, several factors can impact the lifespan of a mini brushless motor. For instance, if a motor is operated beyond its design parameters or exposed to adverse conditions, its performance will degrade rapidly and its lifespan will be reduced. Similarly, improper maintenance practices can cause the motor to wear quickly, leading to increased downtime or even motor failure.

Ensuring proper operation and maintenance is essential for prolonging the lifespan of miniature brushless motor. Appropriate installation practices, regular maintenance, and an adequate supply of clean power can help extend the motor's lifespan. Regular inspection of the tiny brushless motor, including part replacement and cleaning, which can help to identify issues before they cause significant damage.

Get Micro Brushless Motors in Bulk Step-by-step

Micro Brushless Motor FAQ

When selecting a brushless motor, critical parameters should be considered. Including rated voltage, rated current, rated speed and power consumption. The motor's size and weight should also be evaluated to make sure it fits the intended application.

3V micro bldc motors are smaller and lighter than many other types of brushless motors, which makes them ideal for use in small-scale applications. However, they are generally less powerful than larger brushless motors.

Yes, but they must be adequately protected from moisture and extreme temperatures that can cause damage.

Yes. A motor driver is essential for controlling the motor's speed, direction of rotation and delivering the precise amounts of current required by the motor. Without a motor driver, the motor would not operate correctly, while its performance and lifespan would be compromised.

Step 1: Determine the voltage and current requirements of the brushless DC motor.

Step 2: Select a motor controller that matches the motor specifications.

Step 3: Connect the brushless DC motor to the motor controller according to the manufacturer's instructions.

Step 4: Connect power to the motor controller, making sure the voltage and current ratings meet the requirements of the motor and controller.

Step 5: Configure the motor controller settings, including the desired speed, direction, and current limits for the motor.

Step 6: Establish a connection between the motor controller and the control system or interface that sends commands to the motor.

Step 7: Use a control system or interface to send commands to the motor controller, such as start, stop, change speed or direction.

Step 8: Monitor the performance of the motor and, if necessary, adjust the motor controller settings to optimize operation or resolve any issues.

Step 9: Once completed, safely disconnect the motor from the motor controller and power source.

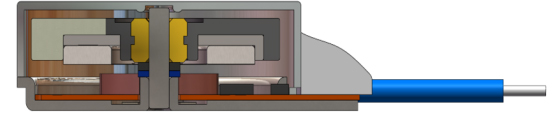

Brushless DC vibration motors, also known as BLDC motors. Brushless coin vibration motors usually consist of a circular stator and an eccentric disc rotor located therein. The rotor consists of permanent magnets surrounded by coils of wire fixed to the stator. When an electric current is applied to the coil, it creates a magnetic field that interacts with the magnets on the rotor, causing it to spin rapidly. This rotational motion creates vibrations that are transmitted to the surface where they are mounted, creating a buzzing or vibrating effect.

One of the advantages of brushless motors is that they have no carbon brushes, which eliminates the issue of wear over time, making them highly reliable and efficient.

These motors have a significantly longer service life than traditional coin brushing motors, often at least 10 times longer. In the test mode where the motor operates in a cycle of 0.5 seconds on and 0.5 seconds off, the total life span can reach 1 million times. It is worth noting that brushless motors with integrated drivers must not be driven in reverse, otherwise the driver IC may be damaged. It is recommended to connect the motor leads by connecting the positive voltage to the red (+) lead wire and the negative voltage to the black (-) lead wire

A small brushless motor is a compact-sized brushless direct current (BLDC) motor designed for applications where space, efficiency, and durability are critical. Unlike brushed motors, it eliminates physical brushes, relying on electronic commutation. These motors are engineered to be miniaturized (often with diameters as small as 5–12mm) while delivering high performance, making them ideal for devices like wearables, medical tools, and compact electronics.

A small BLDC motor operates through electronic commutation (no physical brushes). Here’s a simplified breakdown:

- It consists of a stator(with copper windings) and a rotor(with permanent magnets).

- A controller (driver) sends electrical signals to the stator windings, creating a rotating magnetic field.

- This magnetic field interacts with the rotor’s permanent magnets, causing the rotor to spin.

- Sensors (or sensorless algorithms) detect the rotor’s position, allowing the controller to adjust the current direction in the stator windings—ensuring continuous, smooth rotation.

This design eliminates brush wear, resulting in longer lifespan, higher efficiency, and quieter operation compared to brushed motors.

A micro brushless vibration motor features a compact, flat circular structure optimized for space-constrained applications. It consists of:

- Stator: A miniature printed circuit board (PCB) with integrated copper windings, forming an electromagnetic coil array.

- Rotor: A coin-shaped assembly with permanent magnets (typically rare-earth magnets for high torque density) and an eccentric mass (to generate vibration when rotating).

- Electronic Commutation System: Built-in sensors (or sensorless control algorithms) and a driver circuit to manage current flow in the stator windings, eliminating physical brushes.

The stator windings are energized sequentially by the commutation system, creating a rotating magnetic field. This field interacts with the rotor’s permanent magnets, causing the rotor (with its eccentric mass) to spin. The eccentric mass’s unbalanced rotation generates vibration—the core mechanism for haptic feedback or mechanical stimulation.

To drive a dc brushless vibration motor, you need a BLDC motor driver (controller) that handles three key tasks:

1. Rotor Position Sensing: The driver uses hall effect sensors (or sensorless algorithms like back-EMF detection) to track the rotor’s position.

2. Commutation: Based on the rotor’s position, the driver switches the current direction in the stator windings, maintaining a rotating magnetic field.

3. Speed/Intensity Control: By adjusting voltage or current supplied to the stator, the driver controls the motor’s rotation speed—thereby regulating vibration intensity.

For integration, the driver connects to the motor’s power and signal terminals (e.g., FPCB connectors or lead wires), and the system’s main controller sends commands (e.g., PWM signals) to the driver to adjust vibration patterns or intensity.