Recently, LEADER team worked together with a team from Harbin Institute of Technology to develop a micro vibration motor for application on mobile robots. The research results were published as a Regular Paper in the internationally recognized journal Advanced Science. The research explores a new drive method similar to seal pacing and hopping, which can enable rigid-body robots to realize underdriven straight, arc, steering and other flexible motions. It provides a new idea for the design of single motor-driven mobile robots.

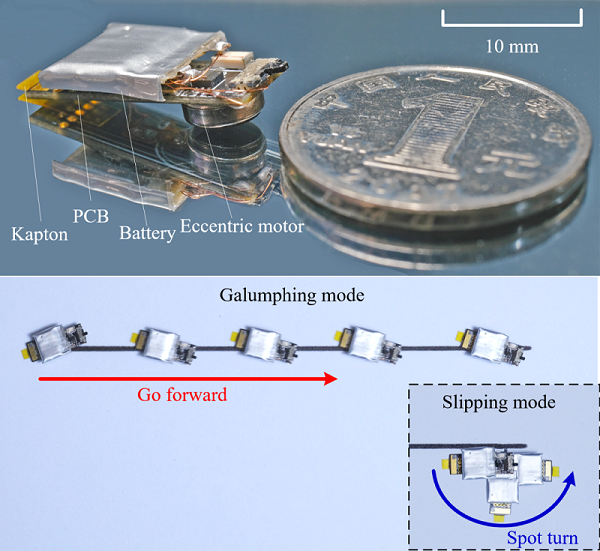

A single motor can also drive forward and turning movements in a plane? That's right, the robot pictured here is called GASR and consists of only four parts: an eccentric motor, a battery, a circuit board and a polyimide sheet. It can flexibly and freely realize forward and turn movements. One of the core driver - button coin type eccentric rotor motor, produced by Leader Micro Electronics. As with the vibration motors in many smart devices, but what exactly is the principle that allows a single driver to achieve such flexible movement?

How is it driven?

Inside the coin motor is a stator and a rotor. The motor vibrates by generating vibrations that drive the model, which is based on the principle of generating electromagnetic forces between the stators.

A single eccentric motor generates a power drive by rotating and converting the drive into the desired linear or rotary motion. Among the types of work in which the drive is realized are straight, arc and steering. Under constant voltage, the motor works on a simple principle whereby the energized voltage can be used to achieve forward and reverse trajectories for the module to achieve a complete cyclic motion. In different constant voltage state module operation can be adjusted according to the size of the voltage to realize the ideal type of movement trajectory.

The miniature vibration motor (ERM Coin Vibration Motor, 7 mm Dia) we provided for Harbin Institute of Technology has the advantages of small size, light weight, low noise and so on. We have our own R & D team, with development capabilities to meet the different needs of customers, combined with the use of customer scenarios for customers to do different styles of customized motors.

Consult Your Leader Experts

We help you avoid the pitfalls to deliver the quality and value your micro brushless motor need, on-time and on budget.

Post time: Feb-29-2024