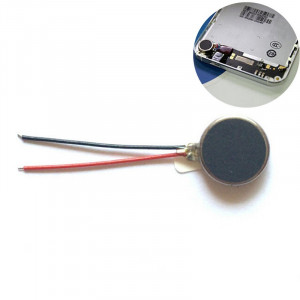

Ho latelaMotor VibralMoetsi, sebopeho sa enthe se na le likarolo tsa motlakase le tsa matla, kahoo liphoso tsa tsona li tla hlahlojoa libakeng tse peli.

Ka kakaretso, ho siuoa ka koloi ho bakoa ke ho se leka-lekane likarolo kapa ho hloleha ha mochini kapa mabaka a motlakase.

1, karolo e potolohang ea ho se leka-lekane e bakoa haholo ke rotor, banyalani, ba khokhothelang thutsong ea nako.

Mokhoa oa ho etsa sena ke ho fumana karolo e kaholimo-equilibrium.f ho na le wheel e kholo ea mopalami lokollotse.

2. Mefokolo ea mekano e kenyelletsa tse latelang:

1) Karolo ea hokahanya ea shafting ha ea nepahala, mohala o bohareng ha o kopane, 'me ho hlophisoa ha hoa nepahala.

Sesosa se ka sehloohong sa mofuta ona oa phoso ke ts'ebetso ea ho kenya, ho infug, ho sa lokang e bakiloeng.

Ho na le nyeoe e 'ngoe, ke hore, karolo e meng ea likhoele tsa mohala o batang, empa kamora ho matha ka nako ea Rotor Fulcrum

2) Ho na le ho hong ho phoso ka gear le bosholu bo tebileng bo aparetsoeng haholo, ho korola hoa mabili, ho nyelisoa, ho koaheloa ke metsi Phoso, ho boloka tumello ho kholo haholo kapa ho senya lintho tse tebileng, ho tla baka mofani o itseng.

3) Lits'oants'o tsa sebopeho le mathata a koloi ka boeona.

Phoso ena e bonahatsoa haholo joalo ka li-slaft molala, litlolo tse ngata haholo kapa tse ngata haholo poleiti ea makoloi le fantisi ea motor

Empa pakeng tsa moqomo le phetisetso ea sehlahla e kholo haholo kapa e nyane haholo ha e ka etsa hore ho hlasimolla empa hape ho ka etsa hore sehlahla e be lubrictal.

4) Moroalo o kentsoeng ke koloi e tsamaisang vibrate.

3, karolo ea ho hloleha ha motlakase e bakoa haholo ke mabaka a khokahano ea enc , deformation Coremation ea Rotor Cleret e bakoang ke vibration.

U kanna oa rata:

Nako ea poso: Aug-31-20199